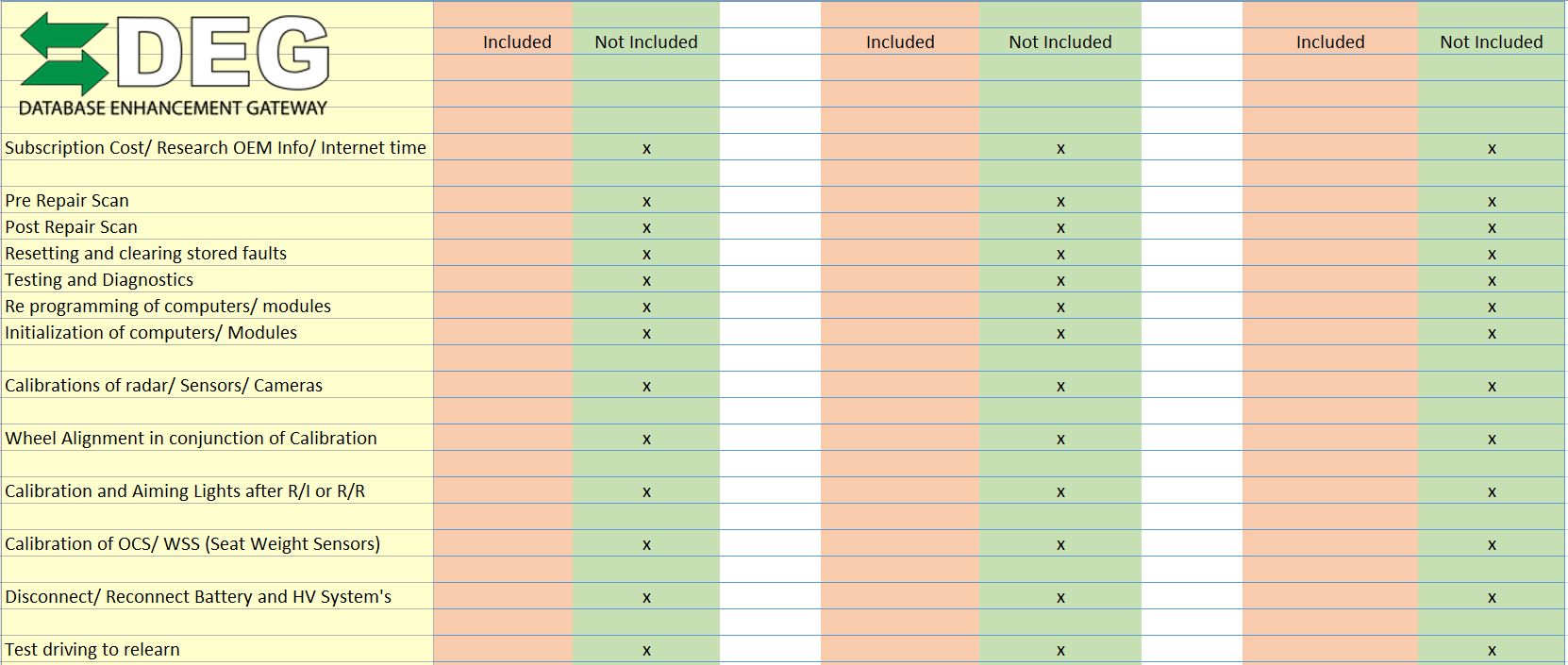

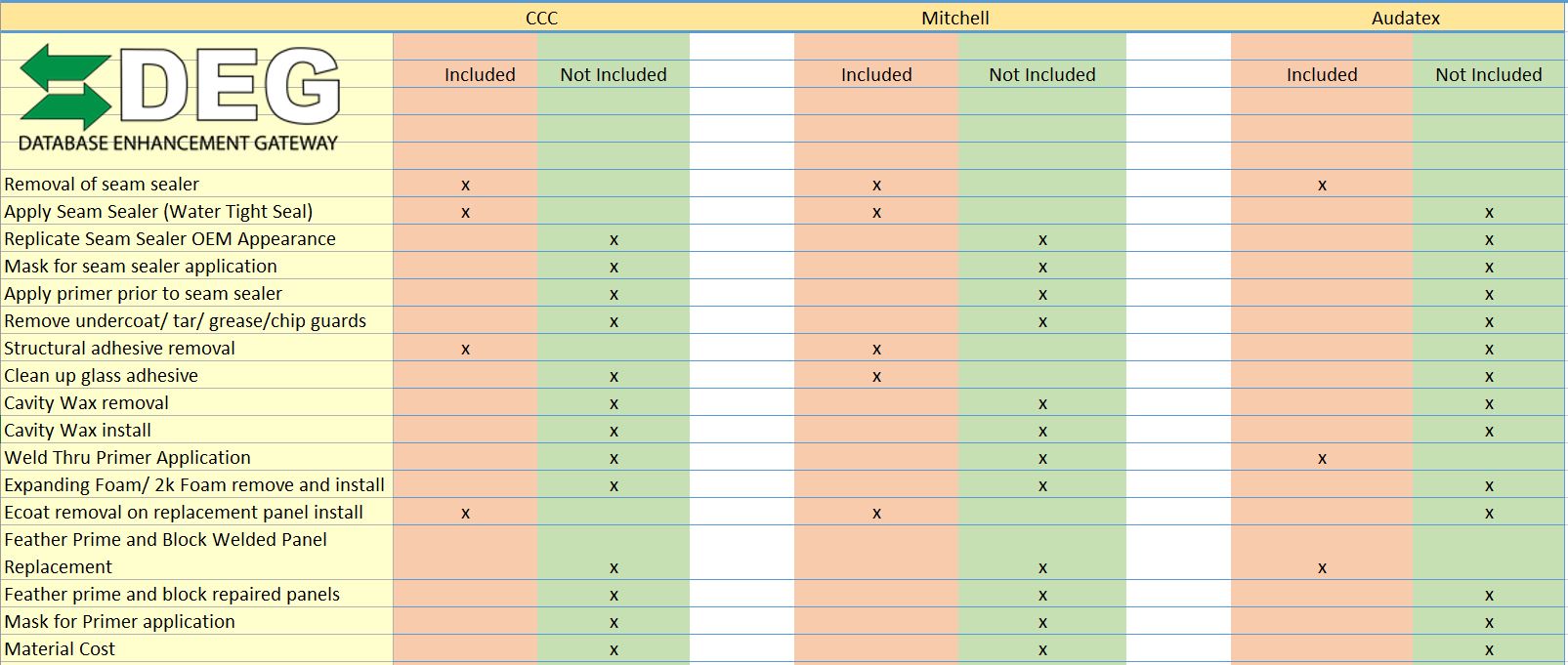

Below are a few items that may help when writing an estimate. Feel free to email us your thoughts or tips. You can follow the DEG on Twitter to receive our weekly estimating tip or send us your email to subscribe today!

Subscribe To Our Weekly Email

"*" indicates required fields

Estimating Tip: Audatex- Frameless Door window

Recent DEG Inquiry 17327 identified Audi Q8 Doors with frameless door window design adds additional horizontal and lateral adjustments for correct fit on the vehicle. Audatex has responded that

“Per the DBRM Audatex labor includes normal adjustment and alignment for correct fit, but does not include any duplicated effort.

“Any additional adjustments needed would have to be a manual entry as we have already accounted for a normal adjustment.”

DEG has confirmed this applies to all vehicles with frameless door window designs where the OEM has provided above and beyond normal adjustments of the window glass to the sealing strips.

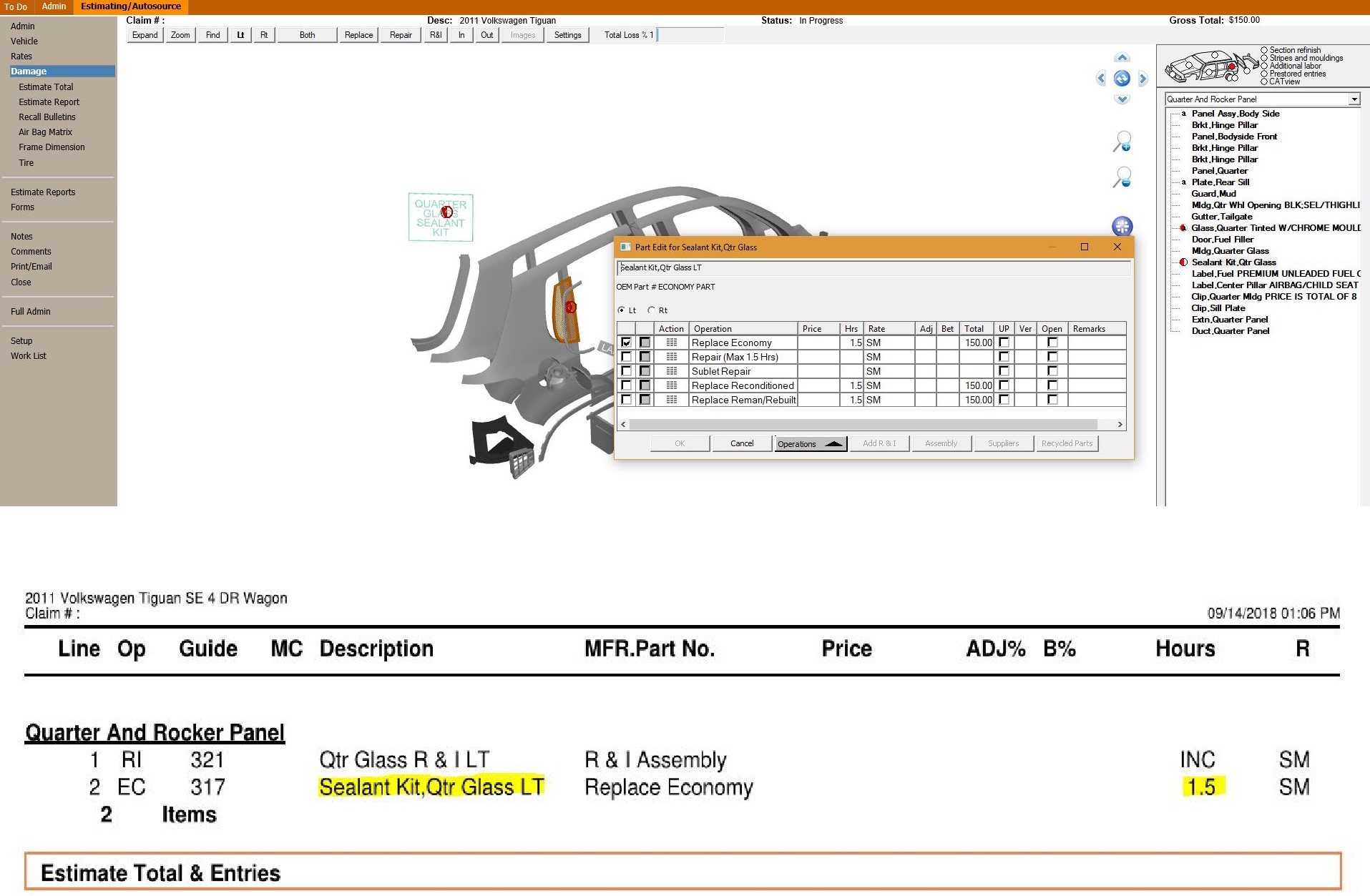

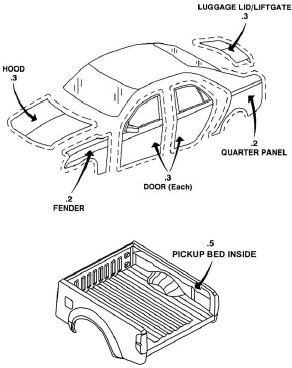

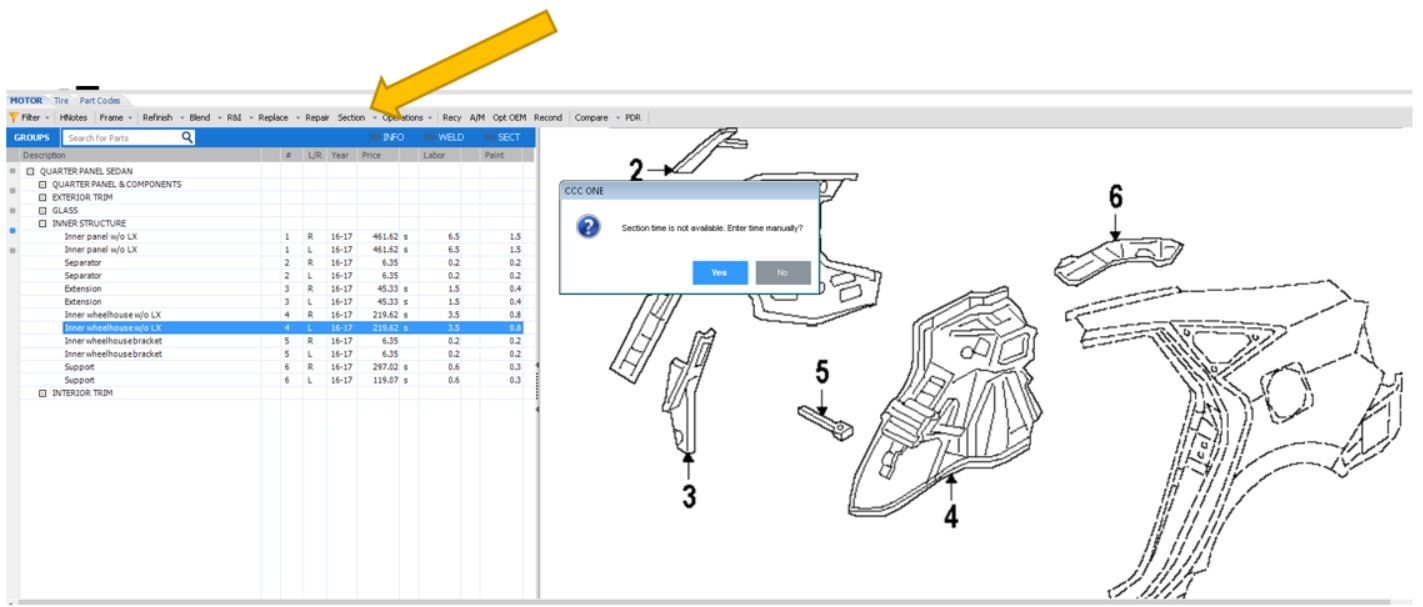

Estimating Tip: CCC – Refinishing “Break Point”

Recent DEG Inquiry 17409 states “After review, when refinishing a “Welded-On Panel” the requirement is to refinish to the nearest “Break-Point”, because creating a Blend-Line at a “Non-Break Point” may result in “Refinish Deterioration”.

Your example; “Repairing the Quarter Panel and the Outer Surface of those parts will require some type of refinishing. The time necessary to perform this type of operation should be estimated after an on-the-spot evaluation of required procedure. MOTOR recommends these factors be considered before finalizing any repair cost estimate.”

“MOTOR feedback: A breakpoint would be a hard stopping point in a undetectable area that may be covered by a molding or the panel edge. The image sent would not be considered a breakpoint or panel edge.”

Estimating Tip: Nissan Wire Harness Repair

Repairs can easily locate wire harness repair kits available from Nissan using Nissan Tech-Mate Tools and Equipment website. Repairs can easily identify connector type using images to ensure the correct OEM part number is being ordered.

Estimating Tip: Audatex –Wire harness attached to bumper covers NOT INCLUDED

Recent DEG Inquiry 17326 Response from Audatex regarding parking sensor harness attached to bumpers during overhaul operation. “We do not allow time on any harness in accordance with Database Reference Manual Section 4-2 Labor Exclusions. No change is warranted at this time.”

An example would be overhauling or replacing a bumper cover with an additional harness attached to the backside of the bumper. Labor to un route and re route the harness is NOT included and would be an on the spot evaluation.

Estimating Tip: Mitchell – Masking within refinished panel perimeter NOT INCLUDED

Recent DEG Inquiry 17278 response from Mitchell states “Perimeter masking is included up to 36 inches, areas requiring masking within the perimeter have not been factored into the refinish allowance.”

An example of masking within perimeter of a panel where masking may not be included is fuel door pocket, Quarter glass openings, door openings, vents and various holes within a panel. This would be an on the spot evaluation.

When exterior panels (i.e. Doors) are remove leaving exposed door openings/entrances, additional masking operation labor times can be found in the Mitchell CEG>> Page 28> Mask Vehicle to prevent overspray . Materials are never included in published labor times.

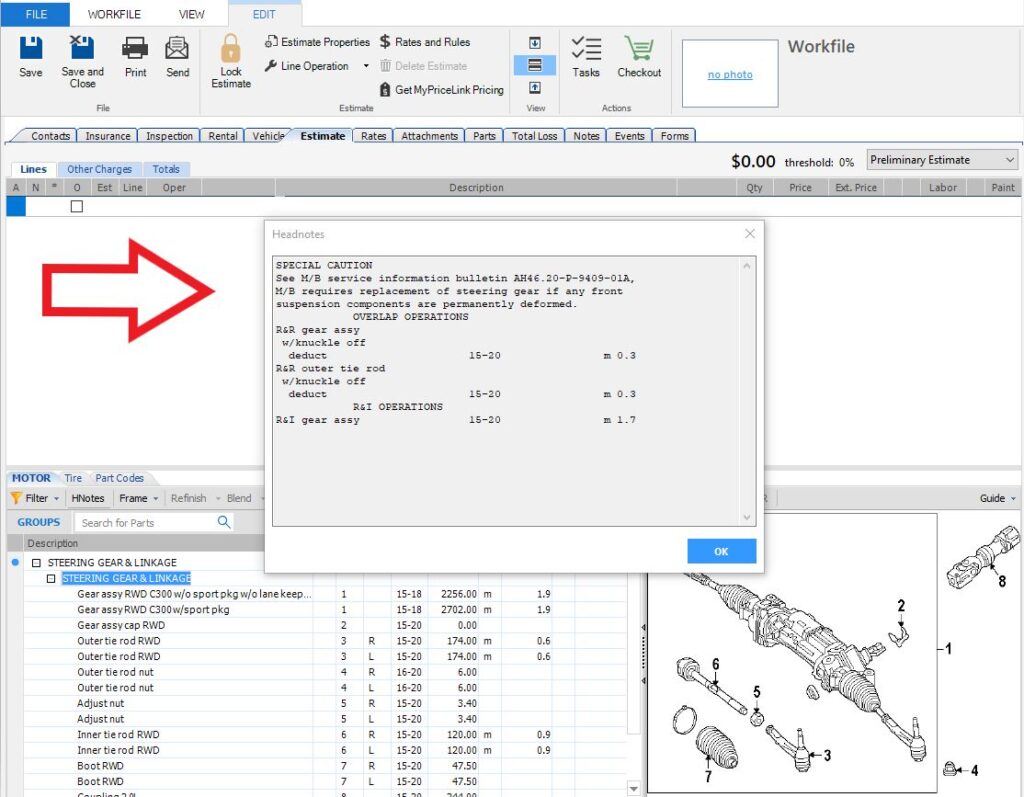

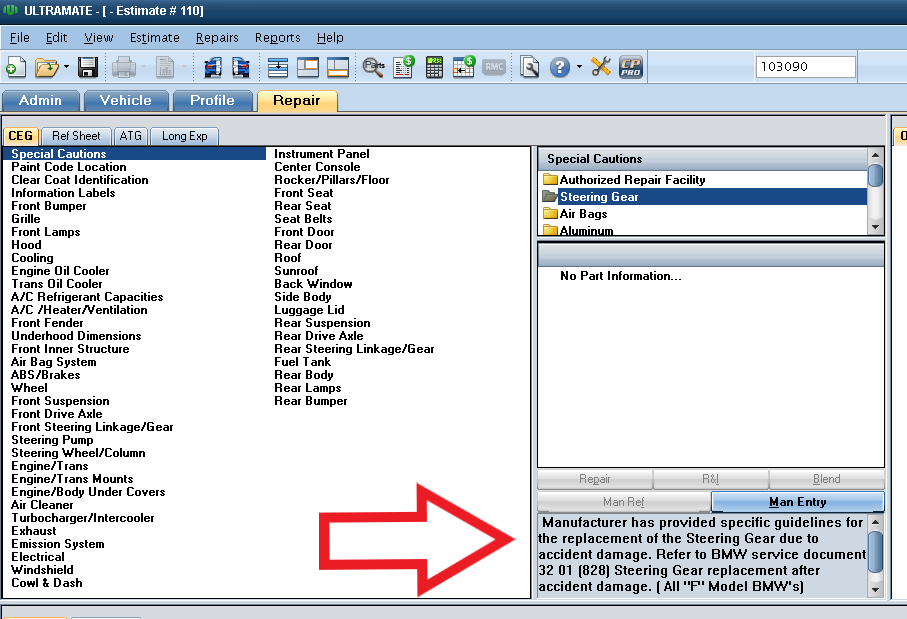

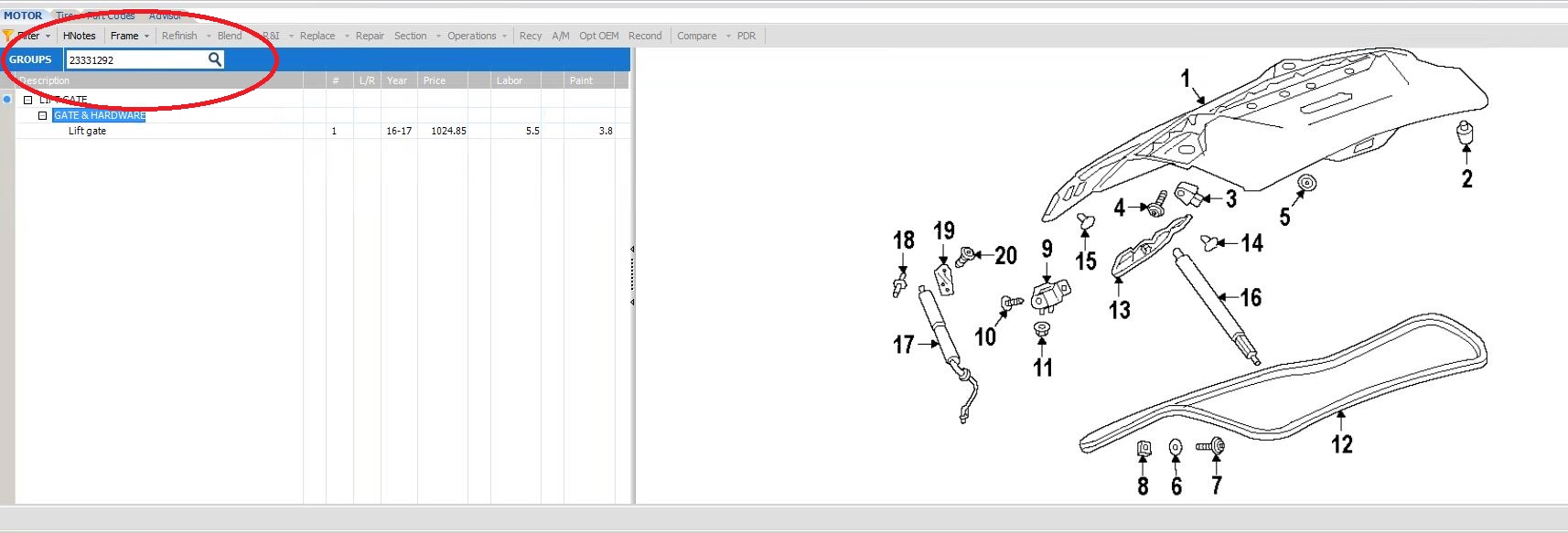

Estimating Tip: H Notes/ Labor Footnotes

Both CCC and Mitchell have H Notes/ Labor Footnotes which may reference important information to consider when repair planning.

Examples of H notes in CCC and Labor Notes in Mitchell may include critical bulletins repairers would need to reference the OEM information about steering gear replacement.

Always verify using OEM repair information for the latest information on the vehicle you are repairing.

Estimating Tip: CCC – Rear Body replacement “Rear Compartment Trim (as necessary)”

Recent DEG Inquiry 17218 states when a user sees a footnote “Rear Compartment Trim (as necessary)” is the general description used to describe any “Trim” that directly attaches to the inside of the “Rear Body Panel”.

Some vehicle where Rear Body compartment trims do not touch the rear body panel, may NOT be included. Users can verify specifics in the footnotes if available or in the GTE P- pages. When a repairer runs across a rear body panel replacement where the rear body trim not touching the rear body panel is still showing included with NO footnotes, please submit a DEG Inquiry for research of the concern.

Estimating Tip: CCC, Mitchell and Audatex- Duplicate R/I and or Fitting operations

Some labor operations in all three estimating systems may included operations which are only accounted for 1 time to be done in the labor operation. If duplicate r/I or fitting operations are done, this would be an on the spot evaluation for additional time needed.

Example would be when loosening of a headliner is included to gain access to a roof mounted antenna. The time to temporarily raise and re lower the headliner while the vehicle is being moved in various repair stages is NOT INCLUDED. Published Labor times are based on 1 continuous operation and does not account for variables in the repair process.

Estimating Tip: Mitchell – Checking & filling Transmission Fluid (ATF)

Inquiry 17115 identified that Checking and Filling ATF is not factored into the Radiator labor time.

Additional labor for Checking, Filling and Fluid cost is NOT included and would be an on the spot evaluation. Always reference OEM Service procedures for necessary operations to refill these components as they can vary beyond filling from the dip stick tube (if equipped).

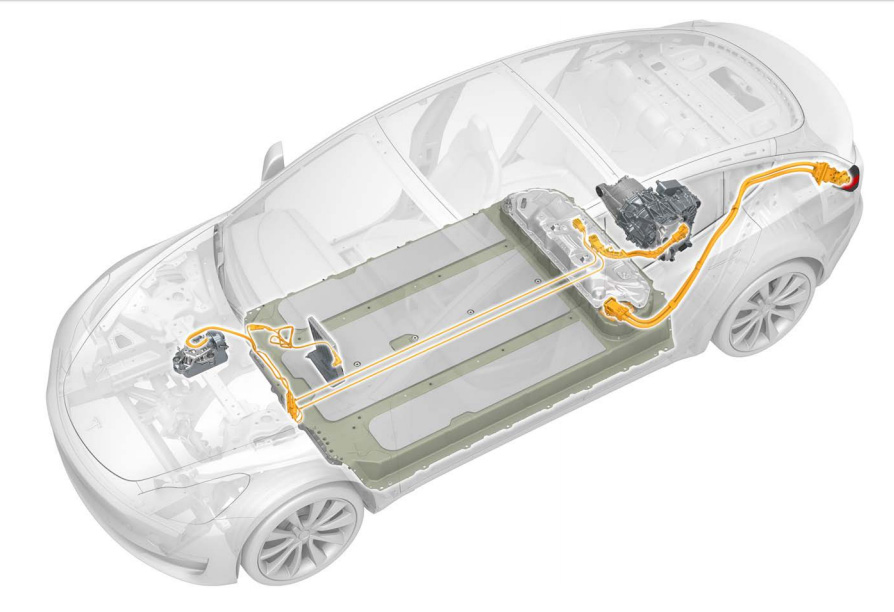

Estimating Tip: Audatex – Tesla Model 3 HV Battery disable

Recent DEG Inquiry 16931 for Audatex has updated the Model 3 HV Battery disable labor and provided feedback about the operation. Some vehicle repairs may require multiple duplicated procedures throughout various repair stages.

“We have reviewed the current OEM service information for the HYBRID BATTERY DISABLE (GN 0702). The labor time has changed from 0.4 hours to 1.0 hours which includes D&R of 12 Volt battery, R&R of HV probe cover and electrical isolation. The time provided for only one iteration as duplicate efforts are excluded as per the Database Reference Manual.”

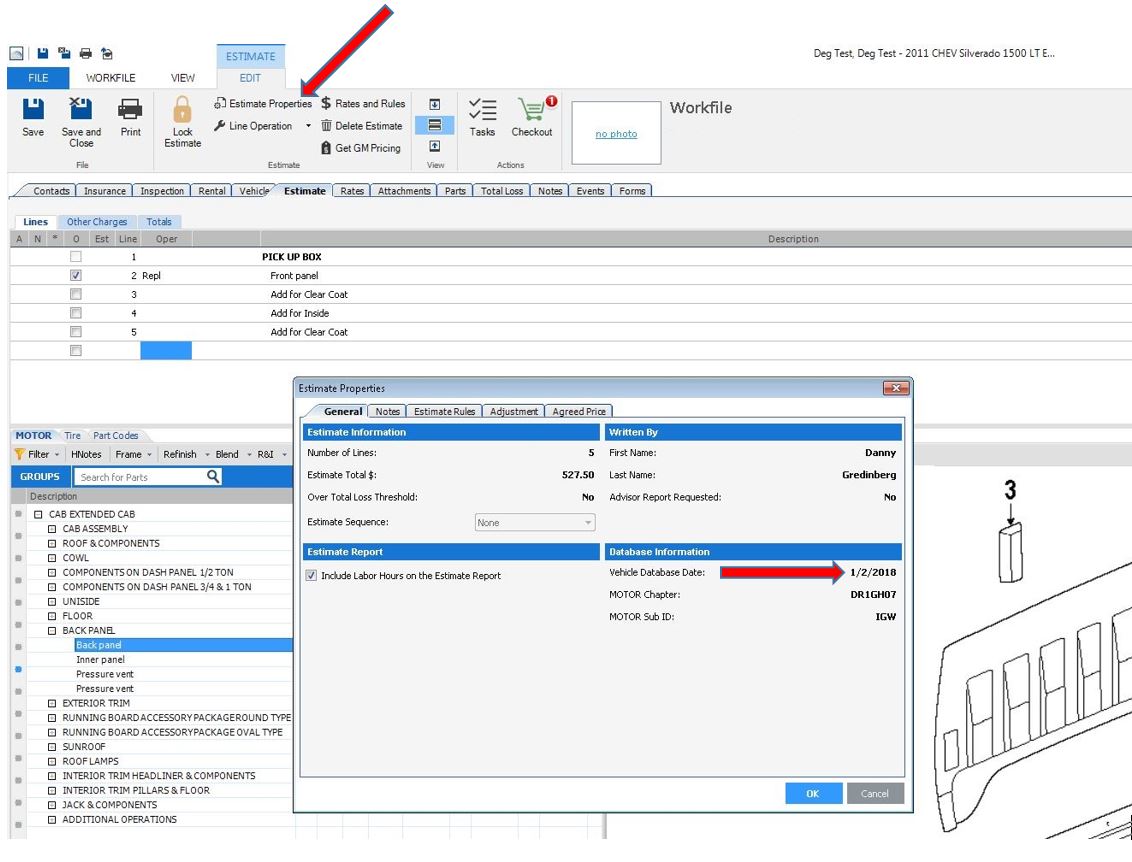

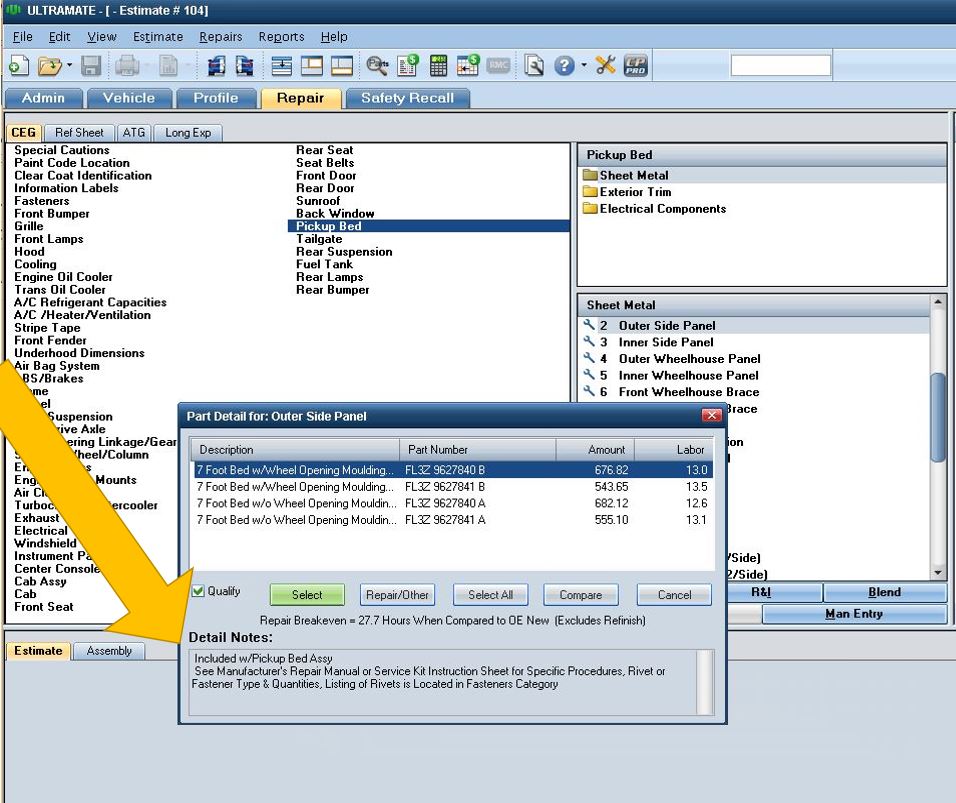

Estimating Tip: CCC – F-150 “Bed Set Back” no longer listed.

Recent DEG Inquiry 17032

“Estimated Release Date: Closed Proposed Resolution: MOTOR stated: After review of the procedural steps for “Set Back Box Assembly” vs “R&I Box Assembly” the same procedural steps are required for both operations. For this vehicle it was determined that “Set Back Box Assembly” requires the same estimated work time as “R&I Box Assembly” there for the operation “Set Back Box Assembly” was deleted. Please note: “Set Back Box Assembly” does not create adequate work space for refinishing operations.”

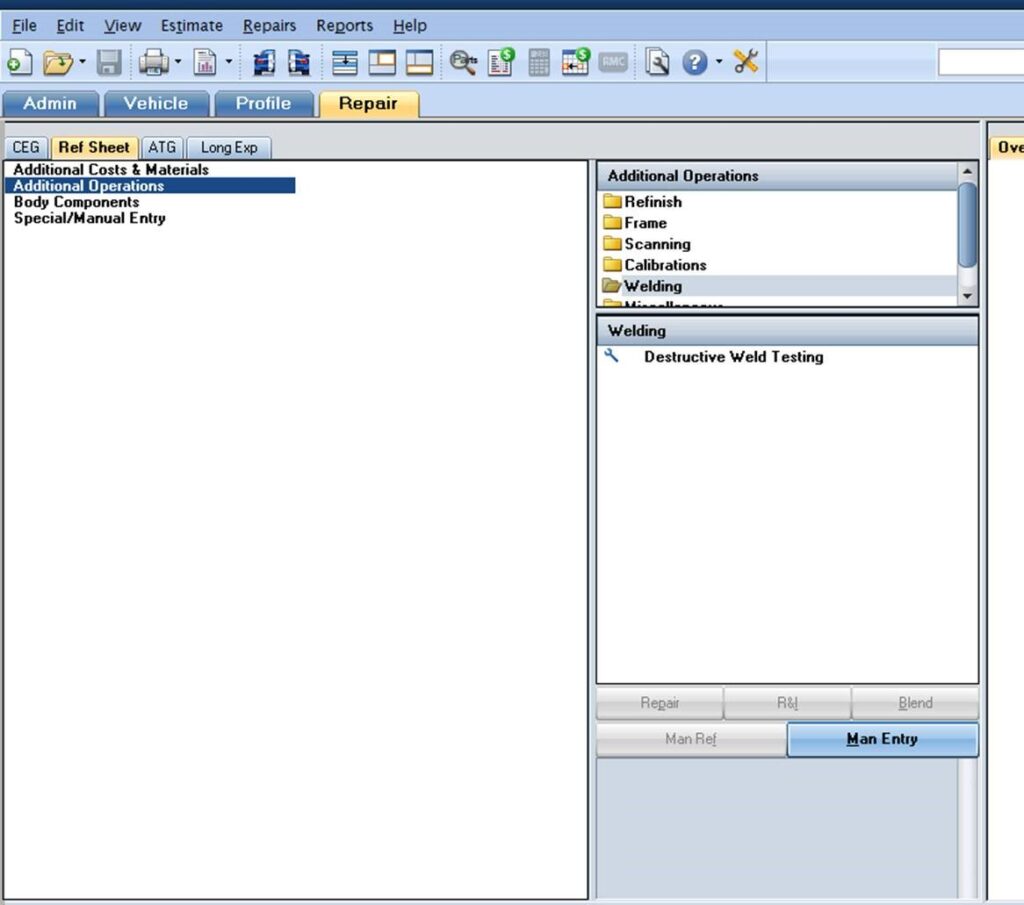

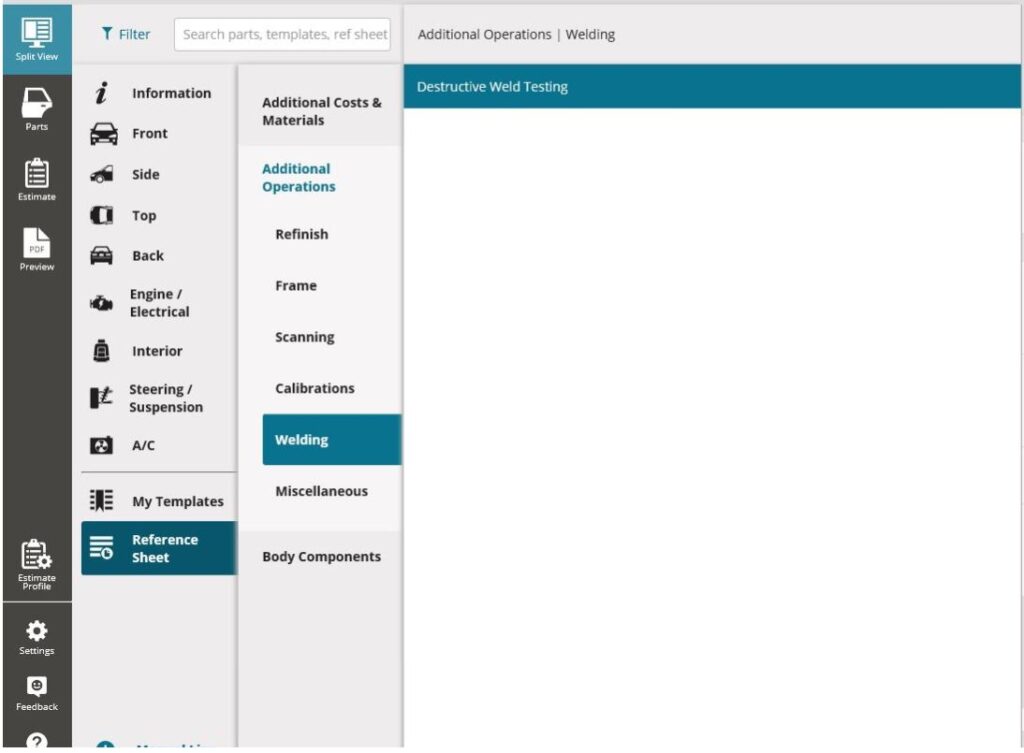

Estimating Tip: Mitchell – Labor for Destructive Weld Testing

Recent updates to Mitchell MCE and ULTRAMATE program will now display “Labor for Destructive Testing as NOT INCLUDED.

Mitchell users can find this operation located in the “Ref Sheet>> Additional Operations>> Welding>> Destructive Weld Testing” in both Mitchell products. This will require an on the spot evaluation.

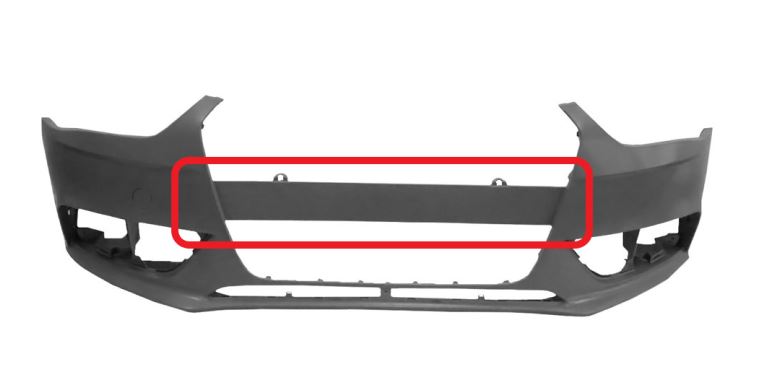

Estimating Tip: CCC – Trimming braces molded into bumpers.

Some replacement parts may be shipped with support bracing that would need to be trimmed away before installing on the car.

Any modifications to the component requiring trimming of unneeded bracing would be NOT INCLUDED. Recent DEG Inquiry 17005 “MOTOR suggests using an on-the-spot evaluation for a mutually agreed upon time.”

Estimating Tip: Access to OEM Owners Manuals FREE!

DEG has compiled a list of links directly to review OEM Owners manuals. Owners manual information may include necessary procedures or requirements not found in the repair manual.

An example of information may include how many tires should be replaced when a tire is damaged requiring replacement.

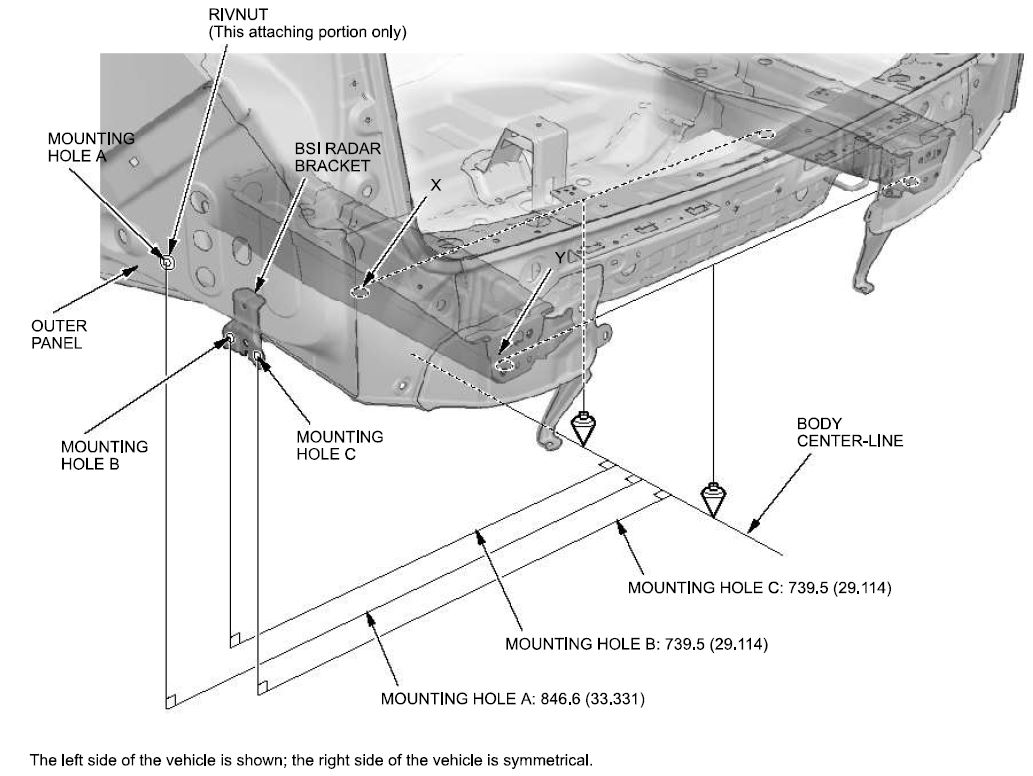

Estimating Tip: CCC, Mitchell and Audatex: Rivnut, Rivstud, Nutsert and misc Attachment Hardware.

Some replacement panels may require additional mounting hardware for attached components. The labor and hardware cost to install these misc. fasteners to the replaced panel are NOT INCLUDED unless specified in the footnotes in the database.

Some fasteners may require a specific tool outlined in the OEM service manual. This would be an on the spot evaluation unless a labor time/footnote already exists in the estimating system.

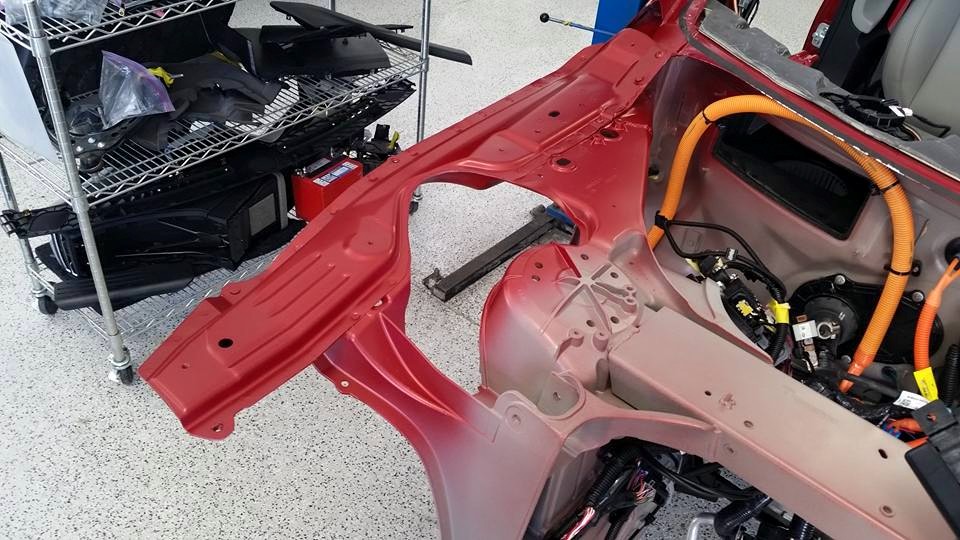

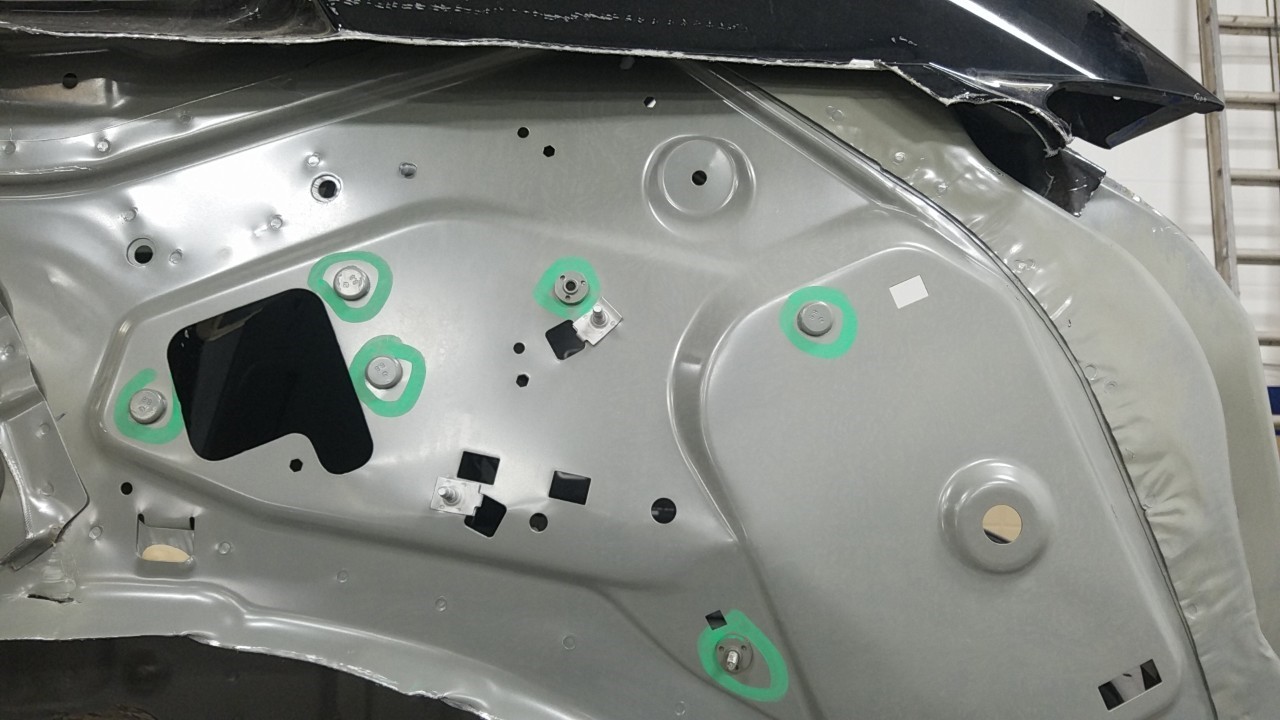

Estimating Tip: Audatex – Section 5-2 FAQ

In 2020 Audatex DBRM was updated with new FAQ (Frequently asked questions) regarding refinishing of the back side of replacement panels.

Question: Does Audatex refinish times allow for refinishing the backside of the panels like fenders and quarter panels?

Answer: The replacement refinish allowance for fenders and quarter panels does not account for refinishing the backside of these panels. They are not typically refinished in the repair process.

Repairers may have instances where the actual backside may not need “REFINISH” but rather additional “Corrosion Protection” product application of labor and materials to replicate the factory appearance and corrosion protection properties. It is always important to reference the OEM’s Repair procedures and following proper corrosion protection steps.

Example below is from Honda 2020 Corrosion protection document

Estimating Tip: CCC – Lowering Headliners for access

Recent DEG Inquiry 16791 addresses when a headliner “lowering” operation is included with another component labor operation time that “If the repair facility decided to remove the headliner rather than raise/re-lower, that would require an on the spot evaluation and manual line entry.

MOTOR cannot predict how many times the shop would need to raise/lower the headliner during a given repair scenario. If the repair scenario requires that to be performed more times than called for in the OEM repair procedure, that would require an on the spot evaluation and manual line entry.”

Estimating Tip: Audatex – Flex Additive Materials NOT INCLUDED

Some repairers may experience a bill payer stating that “Flex additive Materials are included in Audatex”. To clarify this topic, Audatex users should reference the following information in Audatex DBRM guide to clarify the following information on Flex Additive Materials:

On Page 43 Section 4-2 Labor exclusions: “Refinish Materials are NOT INCLUDED in Audatex Refinish Labor Values”

On Page 160 “Add flex additive** (when required, labor only)” is considered an Included operation.

Estimating Tip: Mitchell – Accessing helpful OEM information within Mitchell Ultramate

Estimating Tip: CCC- Additional Operations “Add for Foglamps”

This week’s tip will discuss some changes in how the “add for fog lamp” features will now appear in Additional Operations group in the front bumper section in CCC.

Estimating Tip: Audatex – Feather Prime and Block for welded panel considerations

Estimating Tip: CCC, Mitchell and Audatex: Modifying part and operation type labor times in estimating systems

In this week’s estimating tip, please watch the video showing how modifying a part and or operation type labor time can affect your estimate to adjacent and or attached parts to the component being modified.

Estimating Tip: CCC- Paintless Dent repair (PDR) / Glue Pulling

Recent Inquiry 16631 regarding PDR/ GLUE PULLING states “Paintless Dent Repair, PDR, is not an operation included in the MOTOR collision-estimating database and therefore PDR included and not included operations are not part of the MOTOR Guide to Estimating pages. A glue pull dent may require an on the spot evaluation”

Additional considerations when performing PDR/ Glue Pulling methods may be included:

• Heating the panel for adhesion and to release glue

• Pulling with conventional frame racks or pull towers (Larger Repairs)

• Release solution and cleaning cloths

• Material cost (Glue, Tabs, cleaning agents etc)

Estimating Tip: Audatex – Grille Labor considerations

Recent DEG Inquiry 16535 states “It is not possible to determine if an assembly is delivered completely assembled or requiring some assembly. Therefore, parts that are not delivered as an assembly that will require additional labor to bring the part to the assembly condition will require a labor allowance at the discretion of the end user. ”

An example would be some RAM grilles coming unassembled from the manufacturer requiring additional assembly.

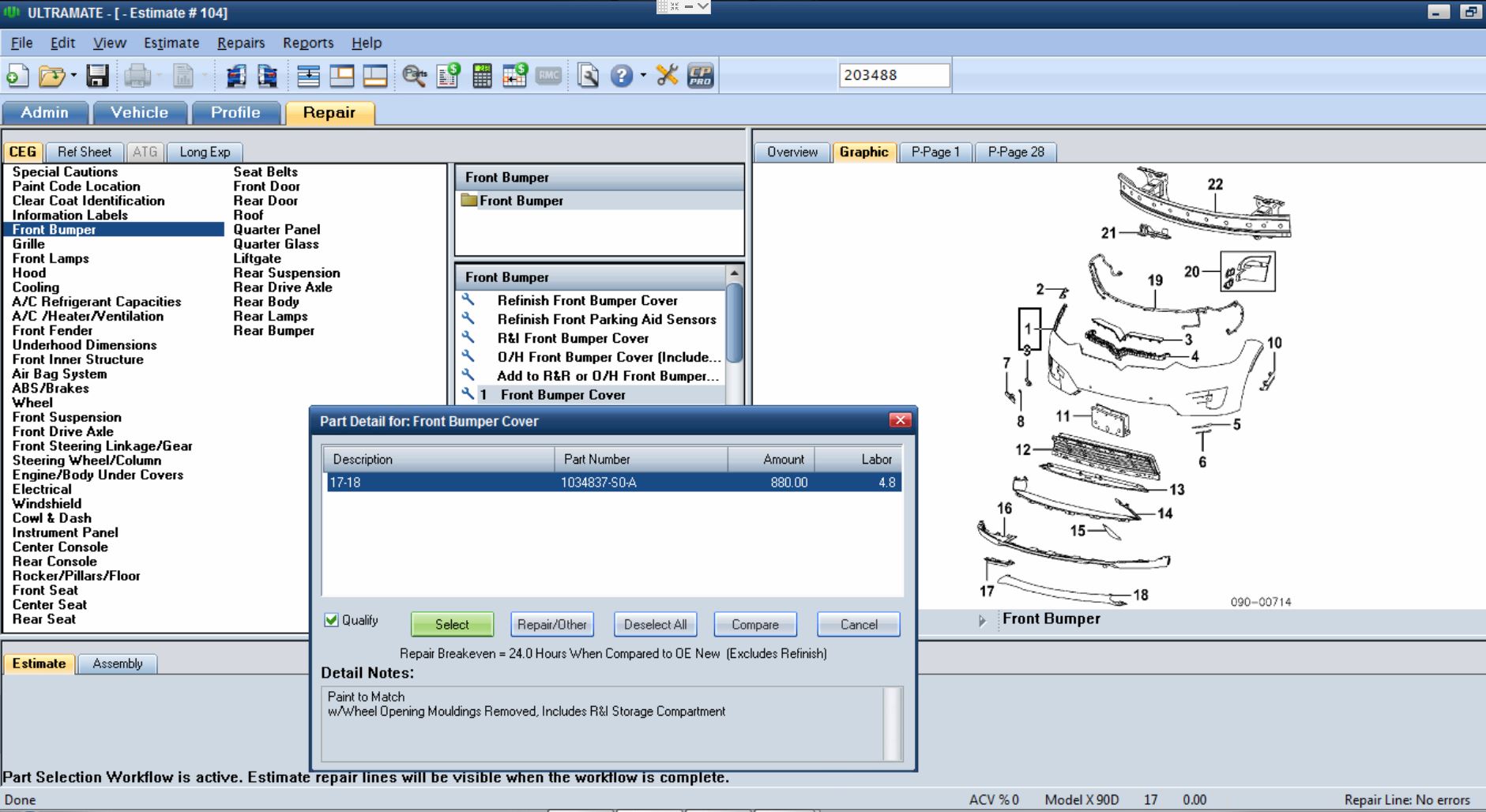

Estimating Tip: Mitchell – Recycled Part Operations (ATG)

Mitchell has made changes in the way Recycled Part labor operations are developed.

Mitchell has provided feedback on inquiry 16546

“In an effort to simplify overlap between the ATG (Assembly time guide) and CEG (Collision Estimating Guide), we no longer publish labor times for bolt on components or assemblies in the ATG.

Operations can be selected from the CEG, and the part type changed to LKQ. CEG labor times, and CEG P-page logic apply.

ATG P-pages do not apply to GEG labor times.

When utilizing an operation from ATG, with a published ATG allowance, the ATG P-pages are applicable.

What would not be included are any considerations for the removal of components serviced with the ATG assembly.”

An example of CEG time on a RECY component would be a RECY door arriving in the same condition of a NEW replacement part.

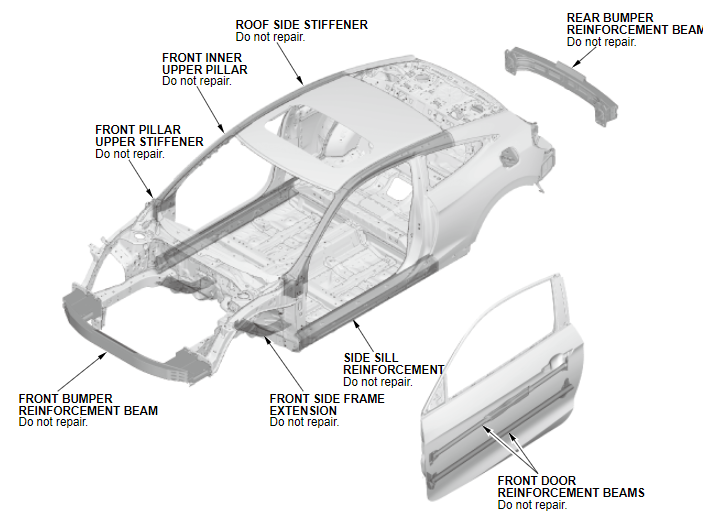

DEG Inquiry 16531 footnote on front bumper reinforcement currently states “Part cannot be reused/ reinstalled”

The current footnote in CCC regarding the reinforcement is an error and has been updated to “”LABOR: Time is after bumper cover is removed. Time not included R&R bumper cover or overhaul.” This change will start to appear on the UM release date 8/3/2020.

Replacement of the reinforcement is NOT needed if the part is not damaged. Please reference up to date repair information from the OEM.

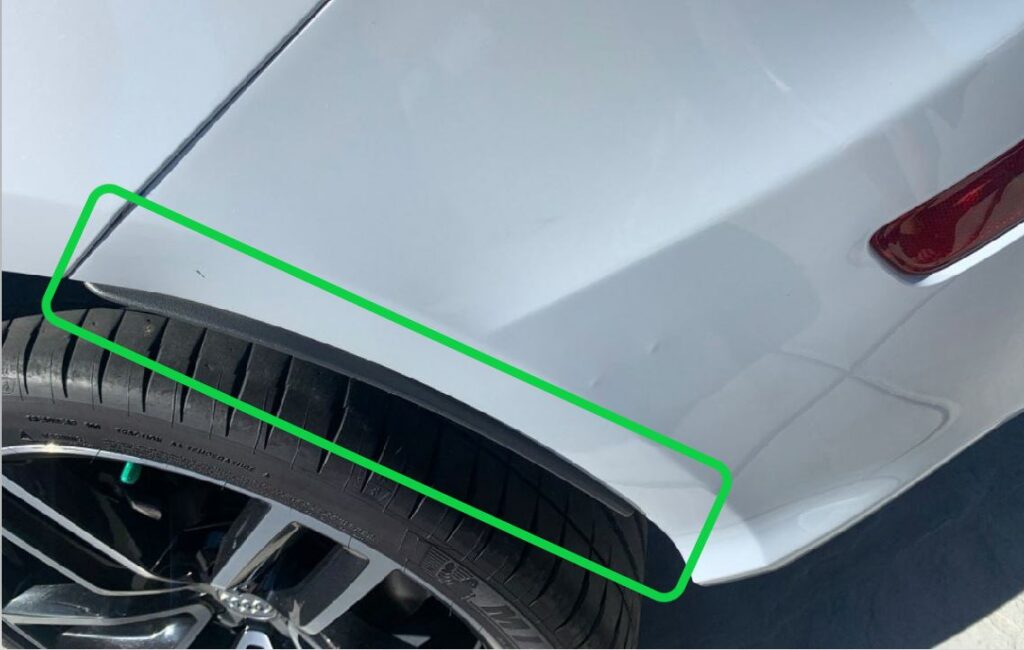

Estimating Tip: CCC- Adhesive wheel opening moldings (Audi Q5)

Inquiry 16513 “Note: The Wheel Opening Molding is standard equipment on the S-Line and SQ5 model Bumper Covers. MOTOR only lists the Wheel Opening Moldings in those bumper groups. The estimated work time is for installation only and is included with R&R and Overhaul.”

In scenarios when a bumper is being O/H for repair, the REMOVAL of the adhesive wheel opening moldings are NOT INCLUDED.

Estimating Tip: CCC and Audatex – Protecting interior during repairs

Various repair procedures may require additional protection to the interior of the vehicle to prevent welding/grinding/ sanding sparks, dust going past the repair zone. Additional consideration for labor and/or materials to protect the vehicle interior is NOT INCLUDED.

CCC DEG Inquiry 13434 “After review of the concern, it has been determined that covering the exterior, interior and components of the vehicle to prevent weld spark damage is not included with welded panel replacement estimated work times.

Determining an estimating work time for these procedures would require an “on the spot evaluation” when developing the estimate.”

Audatex DEG Inquiry 15218 “We have reviewed your inquiry with regards to “Cover to protect interior during repair”. We consider time to place and remove welding blankets only. Any additional operations are not considered in our guidelines. No changes are warranted at this time.”

Estimating Tip: Audatex – Labor consideration for additional technicians

Some procedures may require the use of more than one technician to complete. Examples include team lifting, scan tool operation while driving, large or heavy parts R&I/R&R.

Per DEG Inquiry 16414 Audatex states “Any additional labor for additional technicians to assist with labor tasks are not included. No change warranted at this time.” This will require an on the spot evaluation.

Estimating Tip: CCC – Nissan/ Infiniti Database Information Delay

DEG Inquiry 16423 “The current Nissan/Infiniti vehicle information has been delayed. MOTOR is working with Nissan Motors to secure access to the OEM data required to update the Nissan/Infiniti vehicles to the most current information. MOTOR anticipates releasing this content during the second and third quarters of 2020.”

Additional DEG Note: Please verify part numbers and pricing from your Nissan/ Infiniti parts distributor to ensure correct part numbers and pricing before finalizing repair cost.

Estimating Tip: CCC, Mitchell and Audatex – Damage Diagnosis

Diagnosing damage beyond a visual assessment may be a time-consuming process during repair planning. Additional time to diagnose the damaged vehicle, research repair information, and locating the root issue to a damaged component is NOT included in any estimated work times. Diagnosing damage may require multiple methods and tooling. This would be an on the spot evaluation.

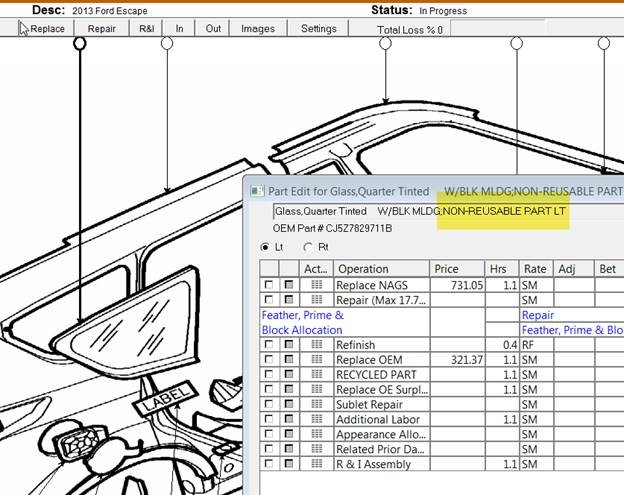

Estimating Tip: Audatex – Non-Reusable Parts Abbreviation

Non Reusable Parts Abbreviation and Pennsylvania Abbreviation Page Update

A new abbreviation for non-reusable parts per OEM of NRPOEM will soon be supported as part of the vehicle data.

The State of Pennsylvania (PA) Department of Insurance (DOI) regulations require that all abbreviations that may be found on an estimate be explained to the vehicle owner. To satisfy this requirement, when the user selects PA as the state disclosure, Audatex Estimating prints a PDF page of abbreviations, therefore the PDF that prints when PA state disclosure is selected has been updated with the addition of NRPOEM.

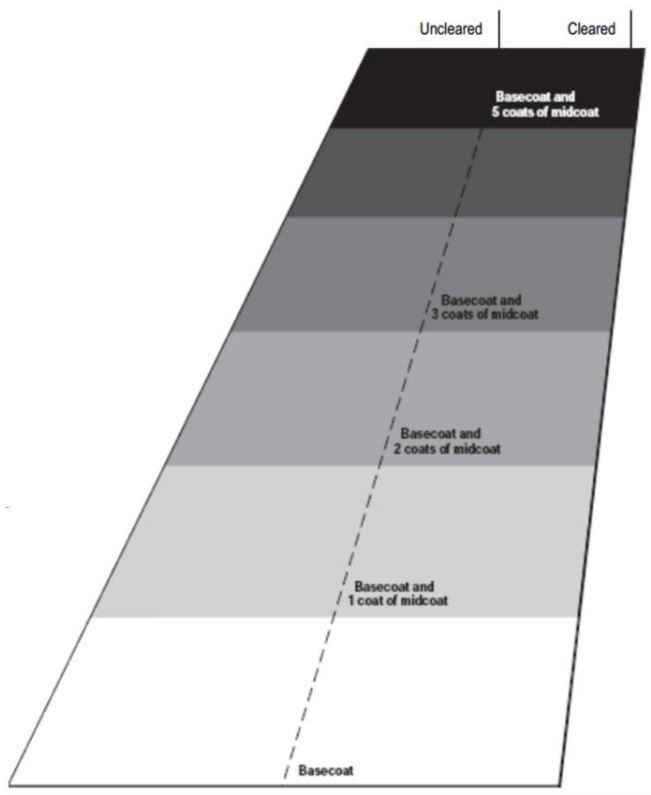

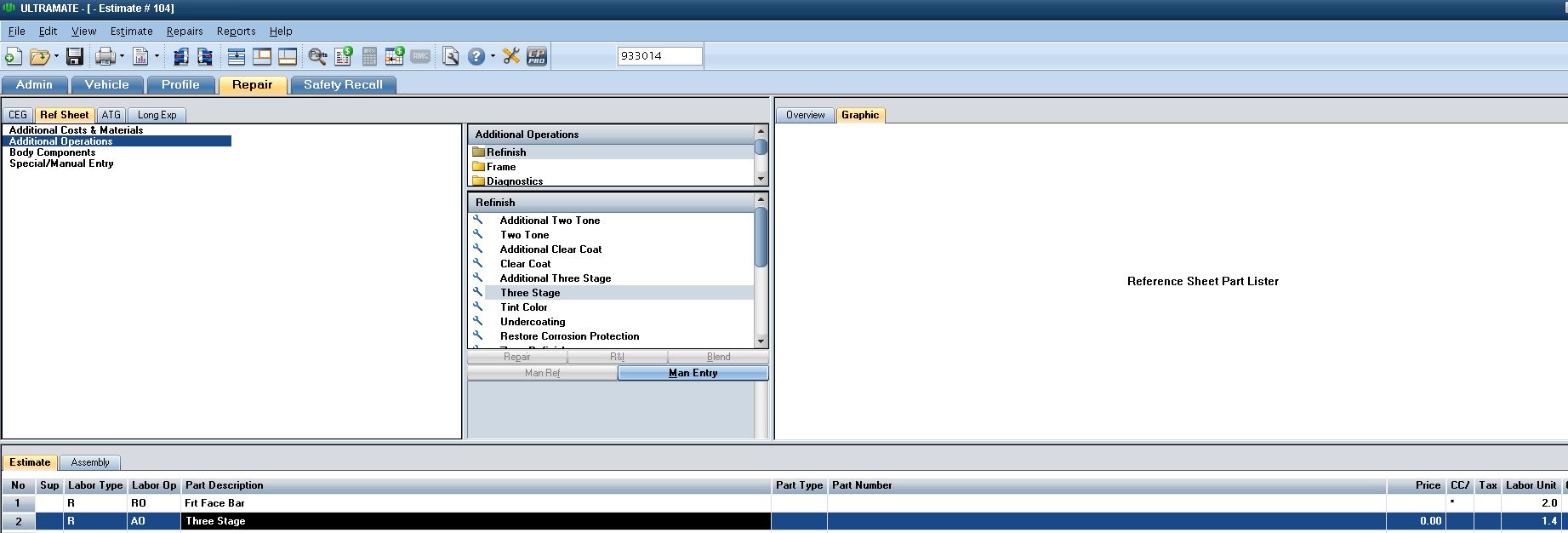

Estimating Tip: Mitchell – Three stage operation: Let Down Panels

Mitchell CEG page 28 Refinish Procedures> Three Stage Refinish state the following operations are INCLUDED:

• Apply toner to let-down panel

• Apply clear to let-down panel

• Repeat application to surface being refinished

Please note: the process is considered included only when performing this step in the same booth cycle as the vehicle itself.

If any part of the let down panel process is done as a separate operation, away from the vehicle, or involves any duplicate operations this would require an on the spot evaluation.

Material costs are NEVER included in any color matching/ let down panel operations.

Estimating Tip: CCC, Mitchell and Audatex: Disconnecting Battery/ negative terminal

Many OEM repair procedures may indicate to disconnect the battery/ negative terminal prior to performing any type of work on the vehicle. DEG Inquiry 16158 response from MOTORS “Per the Guide to Estimating D&R of the battery is a not included item.”

Disconnecting the battery multiple times may be required to facilitate proper disassembly, welding, dent pulling, refinishing process or as necessary per the OEM procedures having to move the vehicle from department to department. If multiple battery disconnects are required, it will require an on the spot evaluation. If the labor footnotes in any estimating system indicates that the labor is INCLUDED, the labor included would be for one disconnect only.

Estimating Tip: CCC, Mitchell and Audatex: Spray out card/ Color Matching Considerations

Neither CCC or Mitchell have assigned labor values for Color Matching/ Spray out card operatations which are considered NOT INCLUDED operations for both. Any labor or materials required to perform color match and or spray out cards, including clear coat and spray equipment set up, would be NOT INCLUDED.

Audatex states on DEG Inquiry 16149 “We have reviewed your inquiry regarding spray test panel process. The spray test panel is not included in the 2 stage set up allowance. It is included in the refinish time and to be conducted at the time of vehicle refinishing. No change is warranted at this time.”

If the spray out card is done in a separate operation away from the vehicle being refinished, any additional or duplicated efforts prior to vehicle refinishing process would be NOT INCLUDED.

Estimating Tip: CCC – Door skin/ Door outer panel replacement repair time

When replacing a door skin, CCC/MOTORS GTE states “straightening of door frame” is NOT INCLUDED.

Additionally, any repairs required to the new door skin/ outer panel after installation are NOT INCLUDED. DEG Inquiry 16087 states:

“• MOTOR does not assign fixed percentages to different steps within a repair procedure.

• The amount of damage and repair needed during the installation of the Outer Panel will vary due to technician skill level.

• Any repair time needed would be an On the Spot evaluation mutually agreed upon by estimators.”

Estimating Tip: CCC, Audatex, Mitchell – Aluminum/ Clean room set up

All three information providers have provided a response to address aluminum/ clean room set up times. CCC and Audatex have stated this is a NOT INCLUDED operation. Mitchell states “NO additional time is needed”.

CCC DEG Inquiry 10980 “ Set up an certified OEM approved Clean Room is not included in the estimated work time.”

AUDATEX DEG Inquiry 11230 “The setup of aluminum room equipment including aluminum vacuum fume and dust extraction have not been considered in labor allowances.”

MITCHELL DEG INQUIRY 13778 “A shop maintaining a dedicated aluminum repair area should not require additional time for Setting up the Clean Room or setting up required extraction systems.”

Estimating Tip: Mitchell – Additional related refinish material calculations

Auto Paint Materials Calculation:

• De-nib & Finesse, Finish Sand and Buff and Mask for Overspray, while coming on the estimate as a “Refinish” Labor Type, do not contribute to the materials calculation when using the “Rates” method.

• While those operations use materials, it is not at the same cost level of primers, hardeners, paint etc… as are applied automatically within UltraMate for core refinish operations.

There are two paths available to the estimator for the application of additional related material costs, as needed:

1. Refinish Materials Calculator (RMC) product provides a separate dollar amount for De-nib & Finesse or Finish Sand and Buff.

• This product is available as a stand-alone or as a Value-Added Feature capability that can be enabled within UltraMate.

+ RMC will also be an available option in Cloud Estimating (MCE) in the future.

2. These costs may also be added as manual line/s and/or Reference Sheet “Additional Costs & Materials” entries.

Estimating Tip: CCC – Air Conditioner Maintenance

CCC/MOTORS has confirmed on majority of vehicles utilizing CCC/MOTORS has confirmed on majority of vehicles utilizing R1234YF AC Systems that 1.4 hours Evacuate and Recharge + .4 hours Refrigerant recovery labor is sufficient.

According to the “Guide To Estimating: AIR CONDITIONER”, “LABOR TIME DOES NOT INCLUDE:

• Cost of refrigerant & oil. or Test for leaks”.

• The maintenance and cost of the A/C machine are not included in the estimated labor time.

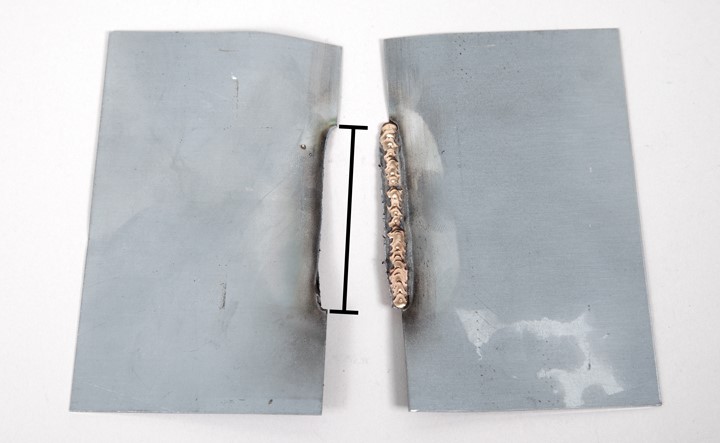

Estimating Tip: CCC, Audatex, Mitchell – Welding equipment set up/ Test Weld

Some OEM repair procedures may indicate various welding techniques in different areas of the repair for a single component. Examples may include a single or combination of STRSW, MAG, MIG or CuSi Braze welding. Consideration to set up and perform a destructive test weld on a single types of weld or multiple weld type may NOT be included in published labor times.

CCC/MOTORS Labor Time premise states: “Welder set-up or preparation” is NOT INCLUDED

Audatex DBRM Page 44 Section 4-2 Labor Exclusions “Setup of welding equipment, welding materials and/or test welding “

Recent Mitchell Inquiry 15359 states “We do not provide information regarding the performance of destructive weld testing. This will be reviewed for consideration in future Procedure Page updates.”

Audatex DBRM Guide Page 48 section 4-3 recent update specifies “Any Sheet metal damage occurring during the separation of sandwiched panels is not included in Audatex provided labor values and would be a manual consideration.”

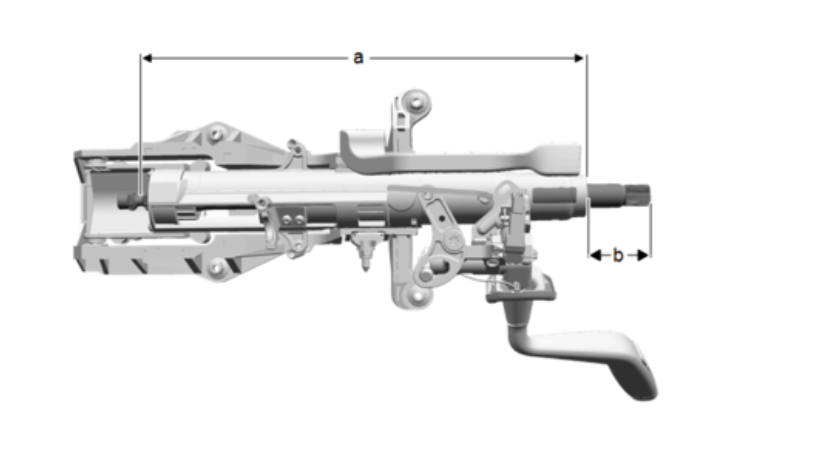

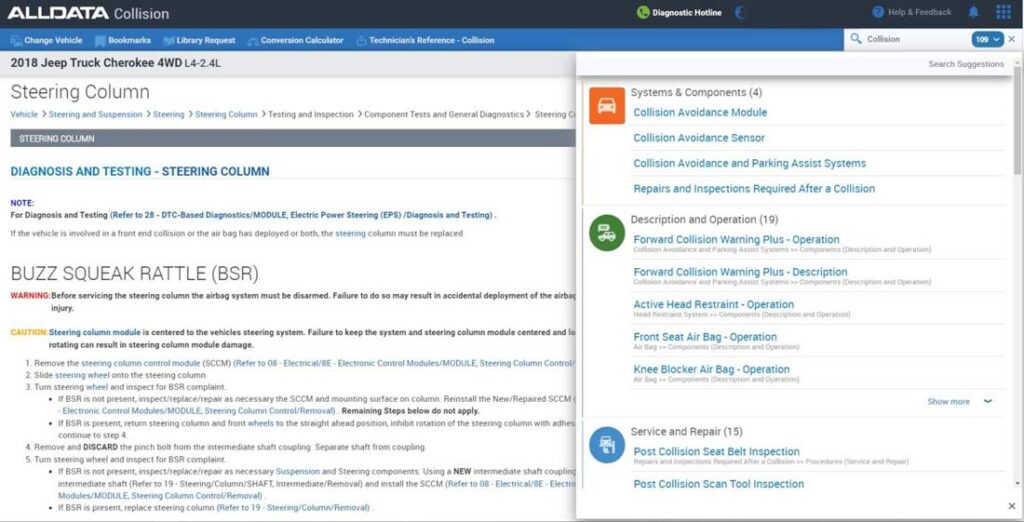

Estimating Tip: CCC, Mitchell and Audatex: Steering Column Inspection

CCC: Many vehicle manufacturers use collapsible steering columns to absorb energy sustained from a collision impact. These columns should be inspected for proper length, binding and deformation among other specific considerations. Failure to do so may prevent proper operation of steering column and/or air bag deployment. MOTOR recommends following vehicle manufacturer’s guidelines for inspection and replacement of these components.

Audatex: Inquiry 15922 on a Subaru states “The Audatex labor allowance does not provide time to perform an inspection for the STEERING COLUMN”

Mitchell: Inquiry 15921 “Mitchell does not develop or publish labor allowances for Steering Column inspection. Please reference Air Bag/SRS Component Inspection and Replacement Tables.”

Some OEM procedures may require the steering column to be removed from the vehicle for measuring and inspection. This process may not be included published R/I times. Please reference the OEM information regarding removal, measurements and one time use hardware.

“Mitchell does not develop or publish labor allowances for Steering Column inspection. Please reference Air Bag/SRS Component Inspection and Replacement Tables.”

Some OEM procedures may require the steering column to be removed from the vehicle for measuring and inspection. This process may not be included published R/I times. Please reference the OEM information regarding removal, measurements and one time use hardware.

Mid-Week Estimating Tip: Disinfecting Vehicles / Work Areas

Amidst this Covid-19 Corona virus, we urge all professionals providing services to take care and caution while working in a public setting. Please follow all CDC recommendations regarding cleanliness and disinfecting your work area.

Due to extra precautions beings set, we want to remind technicians and business that any additional labor/ cost required to create a safe and disinfected work area is NOT factored into published database work times. This will require an on the spot evaluation. Please consult with your managers, owners as well as local and county health officials for any additional information what steps should be taken to create a safe and clean work environment to prevent the spread of this virus.

Examples of creating a clean working environment may include:

• Disinfecting surfaces being touched before and after repairs

• Interior vehicle protection (seats, steering wheels, keys, gear levers)

• Wearing additional PPE.

Estimating Tip: Audatex – Published Pre and Post scan labor time

Audatex has recently started to publish “Pre and Post Scan” labor times. The times being published are specific to vehicle make and model. Audatex has yet to define Included or Not Included steps related to these operations in their Database Reference Manual (DBRM).

DEG has received an official response from Audatex RFR Team:

“Our labor methodology is proprietary. Audatex Pre and Post Scan labor allowances include time for connecting the scan tool, reading any DTCs if applicable, clearing any DTCs if applicable, and disconnecting the scan tool. The times indicated represent using an OEM or OEM equivalent scan tool utilizing the SAE J2534 interface. Any additional work outside of these listed operations would not be included with Pre/Post scan labor allowances provided in Audatex, therefore requiring manual considerations.”

CCC Labor Time Premise currently states “Due to the variety of scan tools used, both OEM and aftermarket, as well as the variation from vehicle to vehicle and repair to repair, MOTOR is unable to develop a time that accounts for these different scenarios. Therefore, MOTOR recommends an on-the-spot evaluation to determine an appropriate estimated time to perform diagnostic scans for each repair.”

Mitchell currently states Additions to Labor Time “Pre/Post Repair Scans- OEM recommendations may include pre/post-repair scan(s) on vehicles involved in a collision to assist in discovery of any specific Diagnostic Trouble Codes (DTC’s). Refer to OEM specific position statement(s) and/or repair procedures for additional information.

All Three: CCC, Mitchell and Audatex: Raw plastic prep/ unprimed plastic components

All three databases recognize raw plastic prep/ unprimed plastic components which may require additional labor to prep and or to prime the plastic component prior to refinish. The automated calculation of this formula only captures front and rear bumpers.

Additional components such as Rockers, Mirror caps or Misc. plastic parts which require additional labor would require a manual entry using the formula provided in the GTE / CEG/ page 143 section 4-4 DBRM.

CCC:

• 25% of the component’s base refinish time

• Maximum time allocation: 1.0 hours

Included: Removal of mold-release agents as outlined by manufacture, masking (if required), Application of adhesion promoter

Not Included: Correction of pre-existent surface imperfections, material cost.

Mitchell: Allow .2 per refinish hour (20%) for plastic components that come from the manufacturer/supplier in a raw/un-primed state. Included Operations: Detergent wash, Alcohol/plastic cleaner wash, Additional solvent wash, Application of specialized adhesion promoter, Clean Equipment.

Audatex: The Audatex formula for preparation of a raw, unprimed Bumper Cover or Plastic Part is:

• 20% of the base refinish labor

Estimating Tip: CCC & Mitchell – Additions to labor times

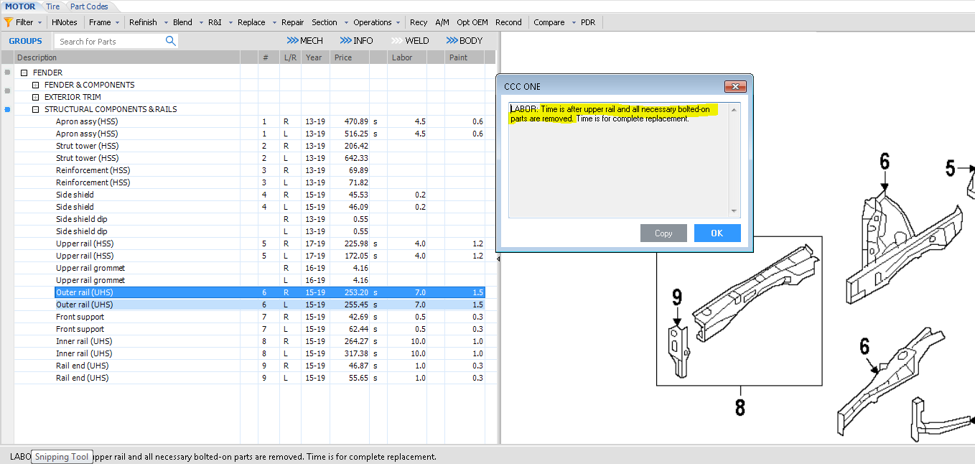

When selecting replacement component labor operations, the footnotes in CCC may indicate the labor is after an overlapping part (welded/ bolted on component) has been removed.

An example would be on a 2017 Nissan Pathfinder front lower rail replacement: “time is after upper rail and all necessary bolted-on parts are removed”

Nissan Service procedures for front lower frame rail states “Work after the hood ledge has been removed”

If the repairer chooses to leave an overlapping/ adjacent component in place and work around the component, any additional labor to repair and or replace would require an on the spot evaluation.

For Mitchell users reference CEG Collision Estimating Guide “Labor General Information” under “Labor Times Section”

Mitchell: CEG Labor General Information states “Times for some operations are applicable after necessary bolted, attached or related parts have been removed”

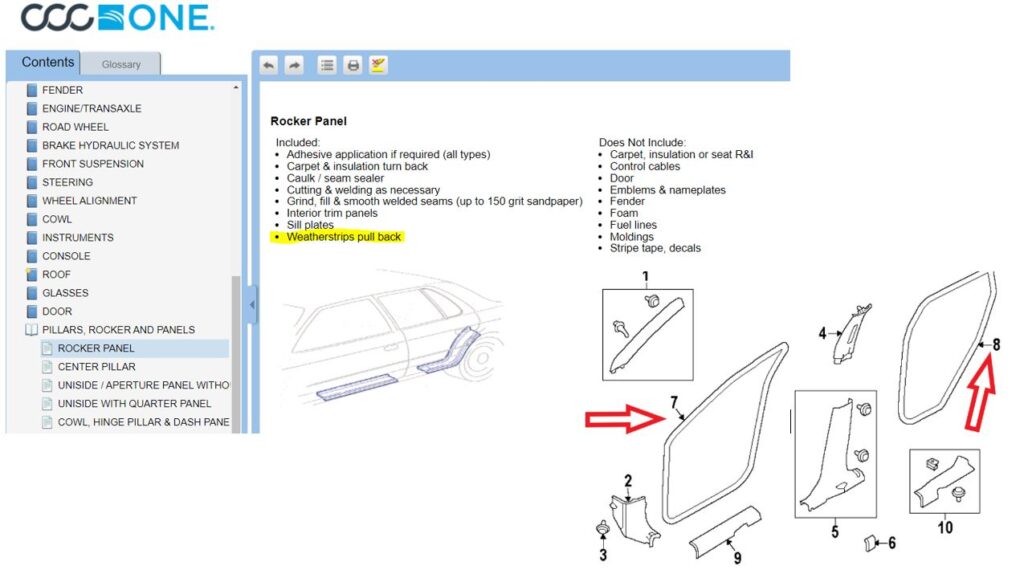

Estimating Tip: CCC: Full weatherstrip R/I not included in rocker replacement

Recent Inquiry 15607 found a database logic error regarding the body weatherstrip showing included in rocker panel replacement/ section. The MOTORS GTE P pages clearly state that “Weatherstrip pull back” is included. When selecting full R/I, the labor defaults to included.

End users would need to make manual line changes when performing a FULL R&I. Confirmed statements from CCC/MOTORS discusses this issue on inquiry 15607 due to logic of rocker and center pillar parts.

Estimating Tip: Audatex – Drain, Refill and/or Top off Windshield Washer Fluid

Recent updates to Audatex DBRM Section 4-2 Labor Exclusions added that “Drain, Refill and/or Top off Windshield Washer Fluid” is NOT INCLUDED in published labor time.

R/I or R/R time for windshield washer reservoir does NOT include to drain or fill the washer fluid.

Washer fluid / additives or Disposal fees to drain/ fill the tank is NOT INCLUDED in labor times.

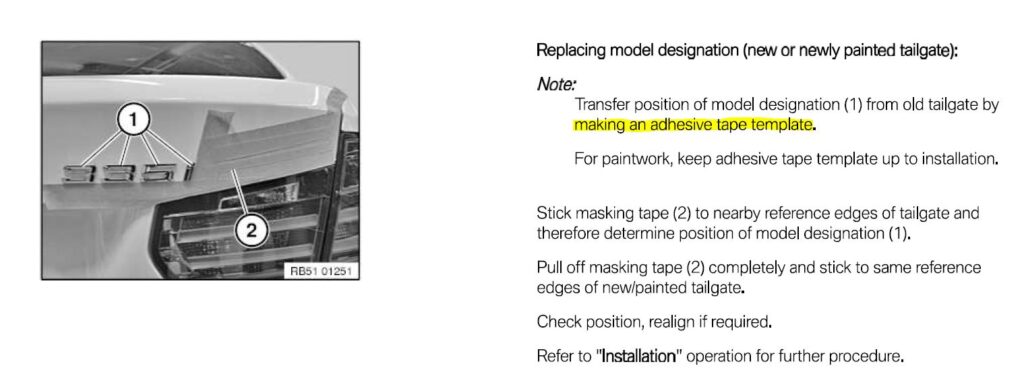

Estimating Tip: CCC: Nameplate template fabricating NOT INCLUDED

Recent DEG INQUIRY 15563 response from MOTORS indicates during replacement of a nameplate/ emblem “After review of the concern, creating templates is not included in estimated work times.”

DEG also points out that “Material cost used to create a template is NOT INCLUDED in labor times.”

Lastly, Per CCC/MOTORS GTE P Pages, the labor time for Nameplates, Emblems, Adhesive backed moldings are for INSTALLATION ONLY. Removal of the molding and cleaning adhesive left behind is NOT INCLUDED in R/R Time. Below is an example from BMW workshop manual indicating to “make and adhesive tape template”

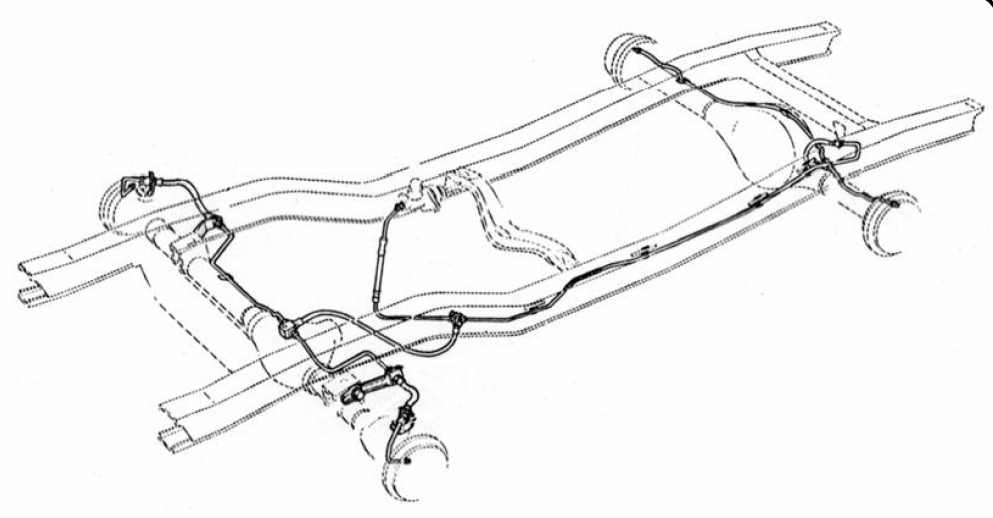

Estimating Tip: Audatex – Frame Rack equipment set up times

Audatex DBRM Page 44 Section 4-2 states

“Setup of a vehicle on a frame machine, dedicated bench, or other measuring / straightening devices. Pulling time is not included (Standard Manual Entry M31 is available).”

Because of all the various types of equipment for repairing vehicle structures, Audatex does not provide a labor value for each equipment requirement for set up/ anchoring and measuring scenarios. This would be an on-the-spot evaluation depending on the type of equipment that is used.

Final DEG Note: It is important to follow OEM procedures and ensuring proper tooling is being used to repair vehicles back to OEM Specifications.

Pictured below is a SPANESI Bench which allows for various types of vehicle anchoring strategies, which will vary from vehicle to vehicle and type of damage involved.

Estimating Tip: Mitchell- Extension of clear coat formula

http://static.mymitchell.com/static/webhelp/ppages/ceg/1033/index.htm#ceg022812.htm

Extension of Clear Coat

In some applications, it may be required to extend the application of clear to the nearest panel edge or breakpoint.

The performance of this operation is NOT INCLUDED in the Mitchell refinish labor time.

The extension of clear coat formula is intended to be calculated as a percentage of base refinish hours excluding overlap.

It DOES NOT APPLY to edges, jambs, and undersides. No deduction for overlap should be taken.

NOTE: When calculated, 20% of the total time should be allocated to the clear coat line item. The total sum of the line and the amount allocated to the clear coat line will total 50% of the exterior refinish time for the panel being refinished.

Example: A panel refinish time is 2.0 hrs. When extending clear, the refinish time for that panel should be 1.0 (.5 per refinish hour). For clarity, the refinish line should be displayed as .8 and .2 (20%) should be allocated to the clear coat line.

We suggest using the “BLEND” selection for any panels requiring this step to ensure properly calculation of the allocated PREP and CLEAR application formula as the system will automatically allocate the 80/20 split of the 50% formula.

Note: This formula is not intended to be used on repaired panels or any panels that require additional labor to repair pre existing surface conditions.

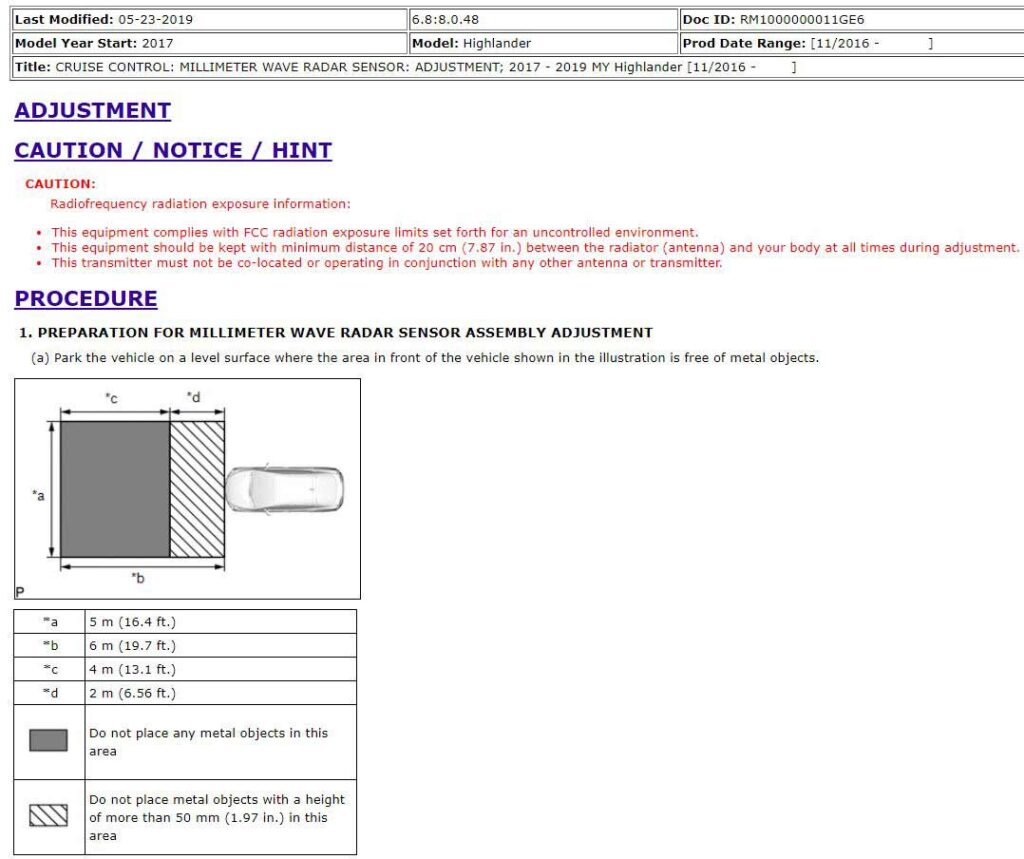

Estimating Tip: CCC – Toyota Front Millimeter wave radar calibrations

CCC users may see labor times for “aiming front distance sensor” available in the vehicle database for 1.0-1.6 hrs.

Recent DEG Inquiry 15393 clarified additional feedback of included/ not included operations.

1. Checking the level of the floor would not be included when a dedicated area is used to perform this calibration. This was done once to determine a dedicated area so it should not be necessary again.

2. Axis Beam confirmation would be included but the adjustment is not

3. The estimated work time includes mapping out the workspace.

4. The estimated time does not include any troubleshooting.

5. The estimated work time includes 1 adjustment.

Estimating Tip: Audatex- Structural adhesive removal NOT INCLUDED

Audatex DBRM Guide page 43 Section 4-2 Labor Exclusions states “Removal of panel bonding adhesive material” is a NOT INCLUDED operation in panel replacement times.

When repairers come across situations where after a panel is removed and the vehicle is left with “panel bonding adhesive material”, the labor associated with removing this material in preparation for the replacement part is NOT INCLUDED. This would be an on the spot evaluation depending on the process, equipment and consumable materials used.

Estimating Tip: CCC, Mitchell and Audatex – Safety Inspections

Required Inspections after a collision are manufacture and vehicle-specific down to the type of impact the vehicle has sustained. Information on what components need to be inspected and/or replaced after a collision can be found in all the OEM technical websites or using a 3rd party program like Alldata.

The labor to perform these inspections is NOT included unless specifically noted in the footnotes of a component being repaired. Some inspections will require selecting components from the database or performing an on the spot evaluation for labor.

During “INSPECTIONS” some components MUST be replaced (Clips, fasteners, repair kits, or specific parts) regardless of the type of impact/ collision. Refer to OEM service information for this prior to finalizing repair planning.

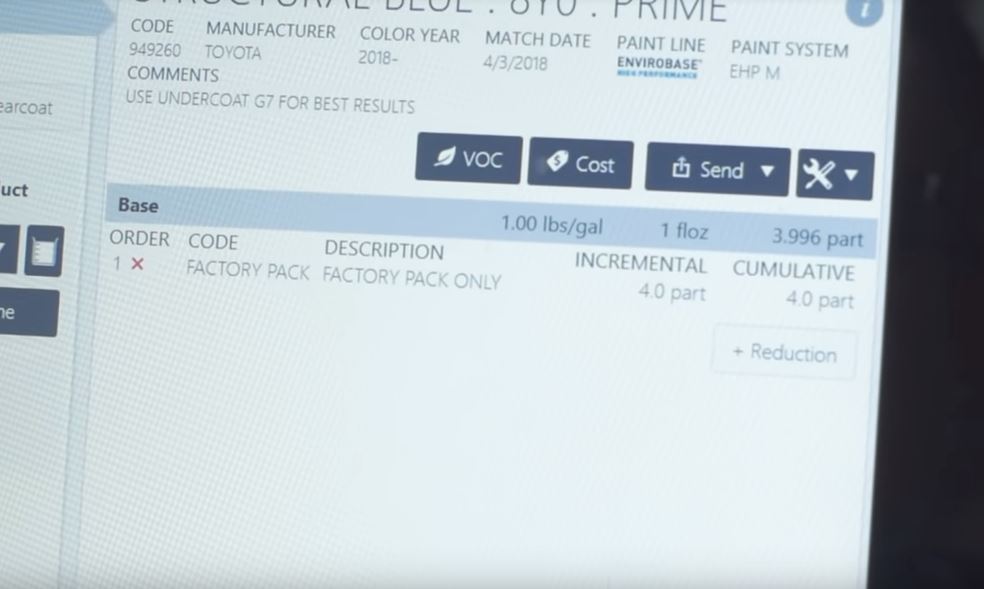

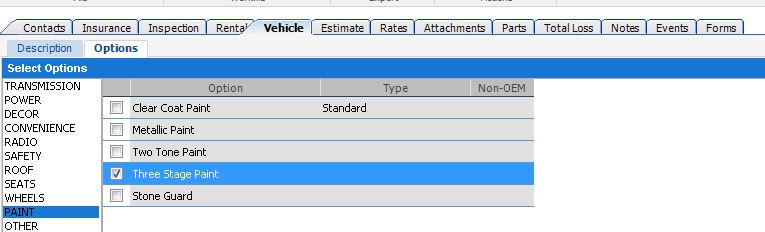

Estimating Tip: CCC, Mitchell and Audatex – Selecting Correct Paint Process Type

CCC, Mitchell, and Audatex may suggest a certain paint code to be a single-stage, base coat / clear coat or three-stage based on major paint manufacture suggestions. Ultimately the type of paint process and paint product used at the repair level needs to be accurately selected from the database for the system to accurately reflect correct labor and material calculations.

Mitchell responded on prior inquiry 15299 “We have seen cases where a specific paint supplier may recommend a unique process for a certain color formulation. Therefore, legitimate considerations can exist on a case-by-case basis for certain colors.

Depending on the paint system used, a three-stage formula may be available. In these instances, it is our recommendation to defer to formula for the paint system being used.”

Estimating Tip: Audatex E-coat (protective coating) Removal on New Replacement Parts

Replacement panels which may require e-coat (protective coatings) to be removed prior to welding, bonding, riveting process are NOT INCLUDED per Audatex DBRM Section 4-2, page 44. The labor toremove any coatings required by the OEM prior to installing the replacement part will require an on the spot evaluation.

Material / supplies used to remove coatings is NOT included in any Audatex labor times.

Estimating Tip: CCC – Filling Additional Fluids into Cooling System

Some radiators/condensers have built-in cooling systems for transmissions, power steering systems.

Labor to replace these cooling units (radiators/condensers) does not include any additional labor that may be needed to fill additional fluids (transmission/power steering/Oils) when being R/I or R/R.

Fluid cost is NOT INCLUDED in CCC labor values.

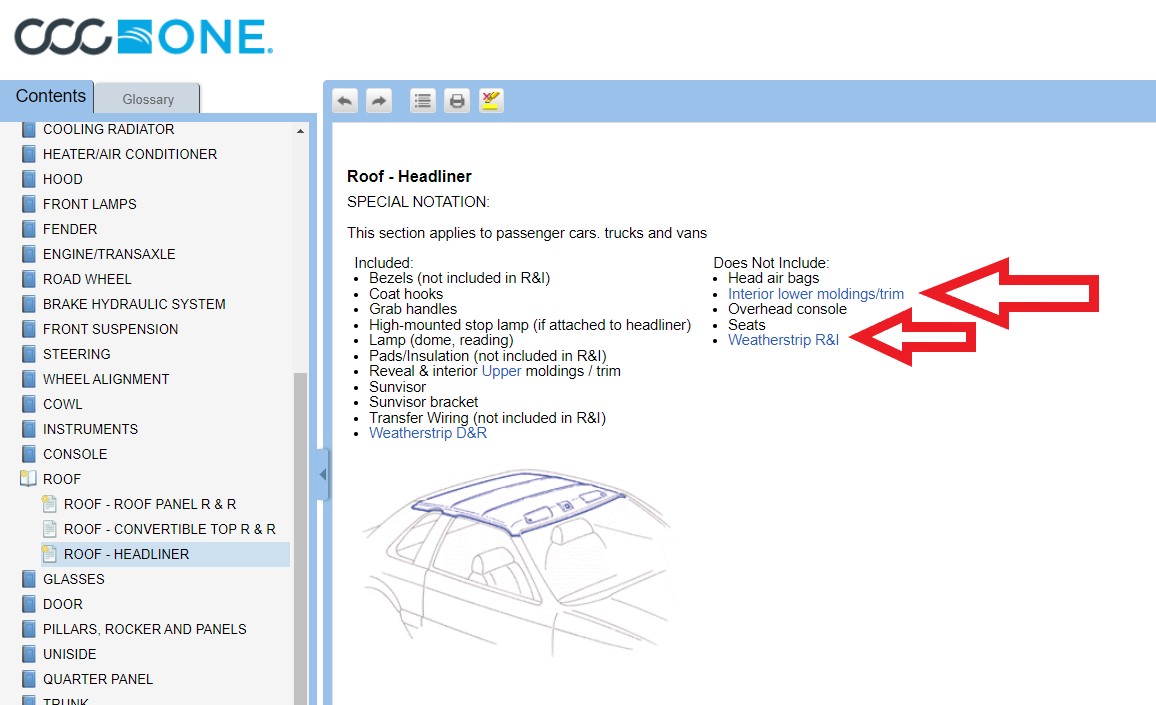

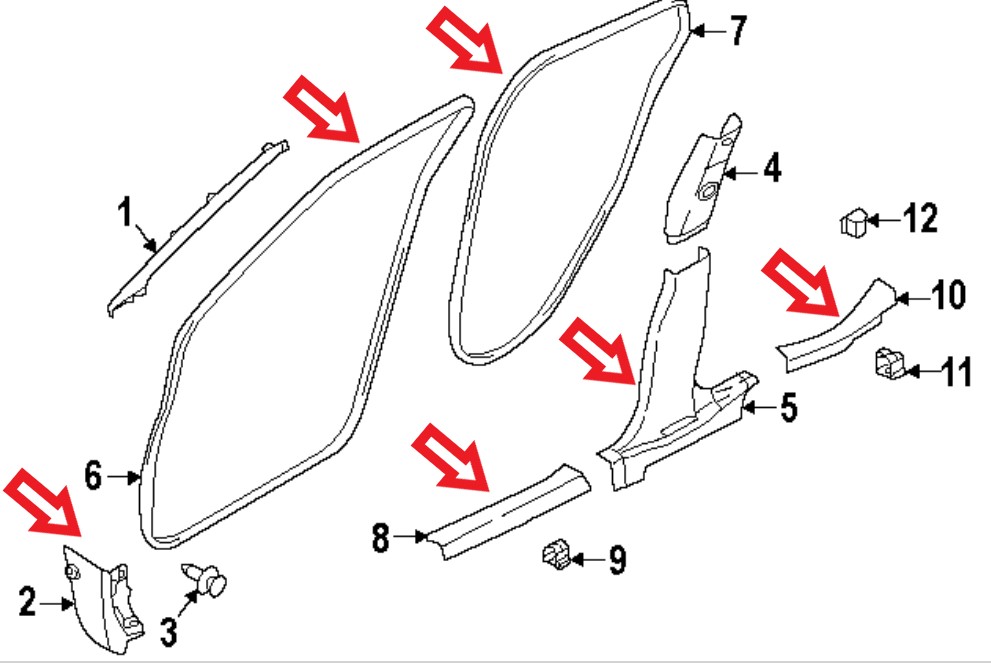

Estimating Tip: CCC – Included / Not Included Headliner Update

11/2019 CCC/MOTORS updated the “HEADLINER” section of the Guide to Estimating P Pages specifically calling out “Interior lower moldings/trim” being NOT INCLUDED as well as “weatherstrip r/I”.

Scenarios where this would be factored is if the lower trims overlap the upper trims touching the headliner. Additionally, some surround weather strips around door openings may be overlapped with additional trims to gain access to the upper trims touching the headliner. This would be NOT INCLUDED as per the GTE.

Lastly, H notes/ footnotes of specific operations would take precedence over the GTE pages.

Estimating Tip: CCC, Mitchell & Audatex – Emblem Adhesive Templates / Clean and Re-taping

Repairers may see scenarios where an “Adhesive Templates” option may be available to reuse existing emblems, nameplates, and badges. When this option is available, typically from a 3rd party supplier, the labor and material associated to prepare the existing part for reuse is NOT INCLUDED in the emblem, nameplate, badge labor time per the estimating system. You may see this component come up as an A/M part when selecting a replacement nameplate, emblem or badge. This is typically serviced as an adhesive backing only that has been precut to mimic the original orientation to reuse the old badge, nameplate, and emblem.

Considerations to reuse an existing part can include the following:

• Cost of replacement Template

• Removal of adhesive from individual lettering/ nameplate

• Applying template onto existing nameplate, badge or emblem

• Trimming any excess material

• Cost of any solutions, adhesion promoters, razor blades

• Any additional repair required to component to be reused

• Measuring, mark and align individual letters for correct spacing

• Some OEM’s list nameplates and emblems as one time use, refer to appropriate repair manual

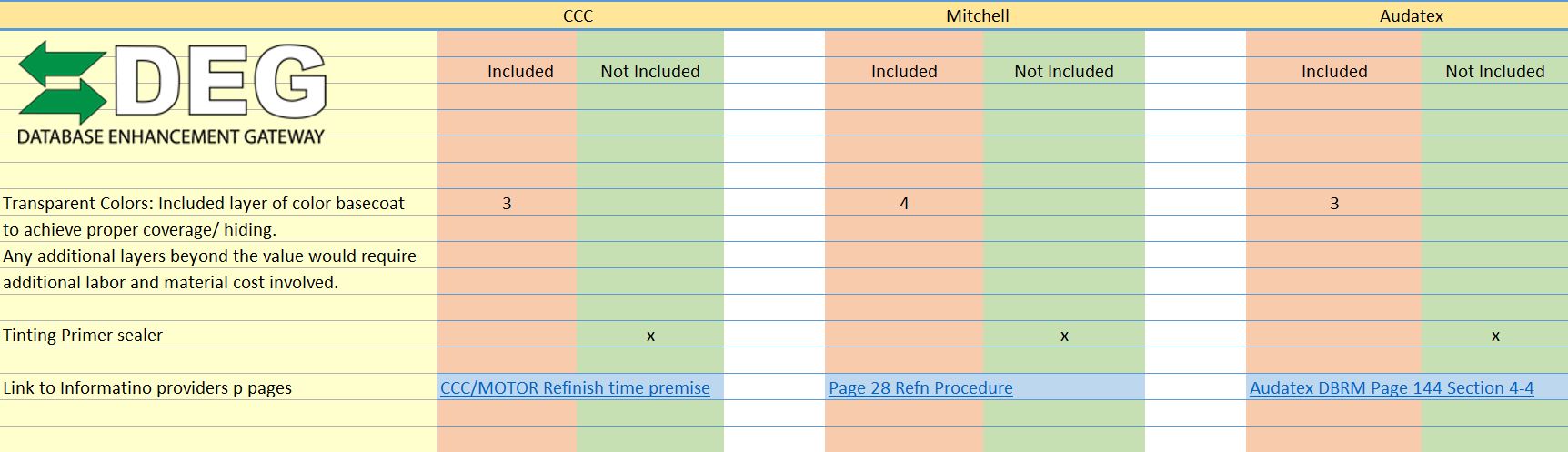

Estimating Tip: Transparent basecoat colors to achieve coverage

DEG has made a quick reference chart showing included and not included operations for Transparent colors to achieve hiding situations.

Link to Excel Sheet: https://degweb.org/wp-content/uploads/2019/11/Quick-reference-transpareny-color-base-coat.xlsx

TRANSLUCENT COLORS

Some colors may need additional applications of material above the normal application of three coats due to pigments being translucent by nature. Any additional application of material for coverage should be considered when developing the estimate and may require an on-the-spot evaluation.

A small percentage of colors are identified by the paint manufacturers as highly transparent . These colors may require additional application coats to achieve visual hiding. In instances where four or more color coats are necessary to achieve adequate hiding, some adjustment in refinish times may be appropriate.

Audatex: http://mysupportgarage.com/documents/10597/69591/Database+Reference+Manual+for+Cars+%26+Light+Trucks

Transparent Colors Some colors have been identified by the paint makers as very transparent. These colors may require tinting the primer/sealer or additional coats of base materials to achieve a correct match (hiding). If this is necessary to achieve a visual color match (hiding), any application of base color beyond the third base coat may require an adjustment of the refinish labor and material allowance.

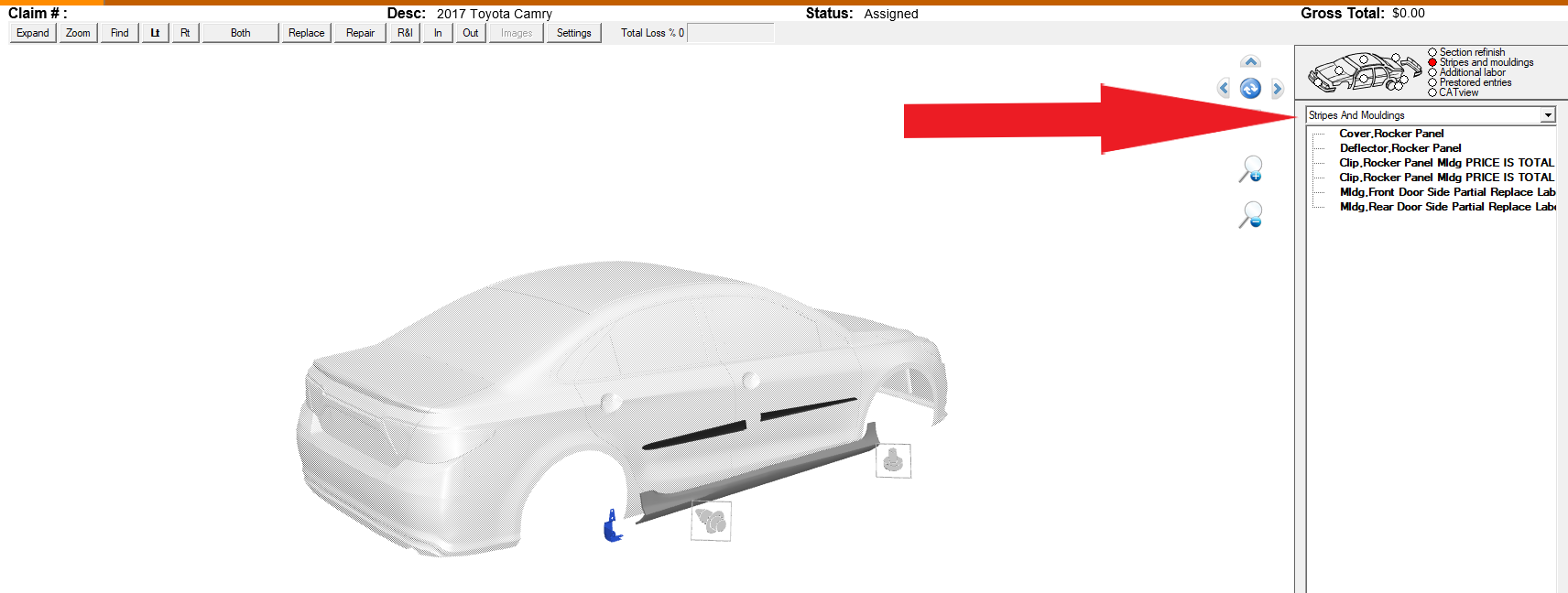

Estimating Tip: Audatex – Rocker Moldings / Body Side Moldings Location

Audatex users will not find the door body side moldings/ rocker moldings in the respective location in the door or rocker group. Users will need to see the “STRIPES AND MOLDINGS” category for the correct part labor and pricing information.

It is also important to ensure the correct vehicle options are selected from the vehicle options tab. Some moldings are considered “optional accessories” and will not default them unless the option is selected correctly.

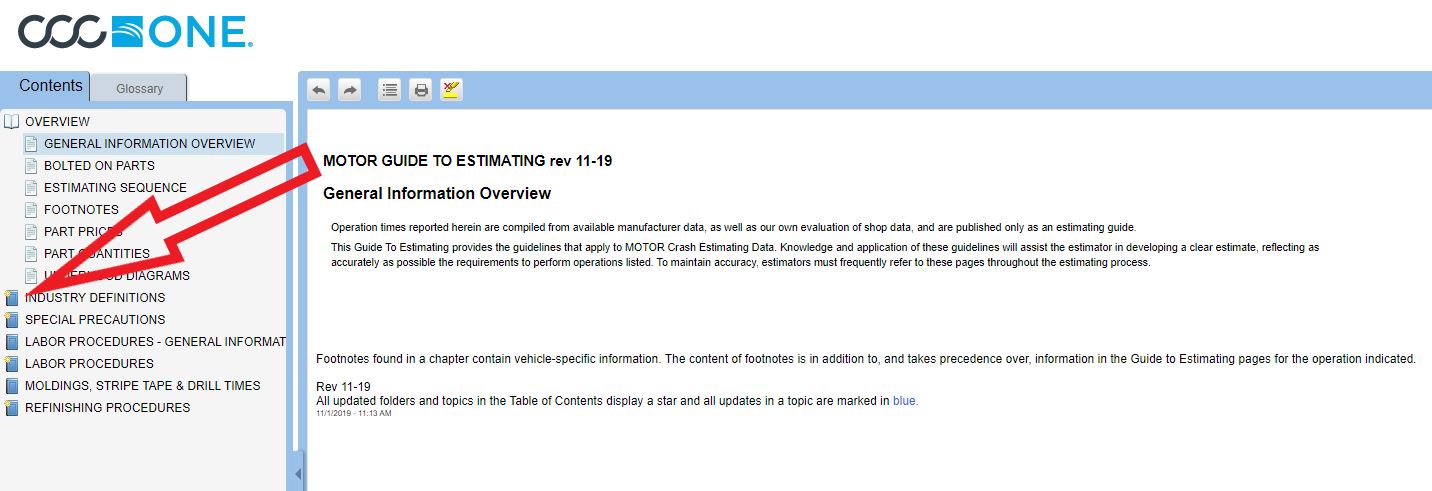

Estimating Tip: CCC – Updated Guide to Estimating (GTE P Pages)

CCC/MOTORS has updated the Guide to Estimating (P Pages). Users can access to most current up to date guide by visiting this link: https://help.cccis.com/webhelp/motor/gte/guide.htm

Users can quickly identify new changes in blue word as well as seeing the new ICON showing an update to that specific section.

Estimating Tip: Audatex DBRM Section 5-2 Frequently asked questions (FAQ’s)

Pages 153-157 of Audatex DBRM Guide provides helpful information to commonly asked questions and provides scenarios and answers about Audatex program.

An example of a question answered in the 5-2

“Question: Does Flex Additive listed in the “Included Operations” include the cost of the flex additive?

Answer: Audatex includes the time in the labor. However, the estimate preparer decides what is, or is not included in the Paint Materials. For additional information, refer to section 4-4 Refinish Guidelines – Paint Materials and Paint Materials and Costs. “

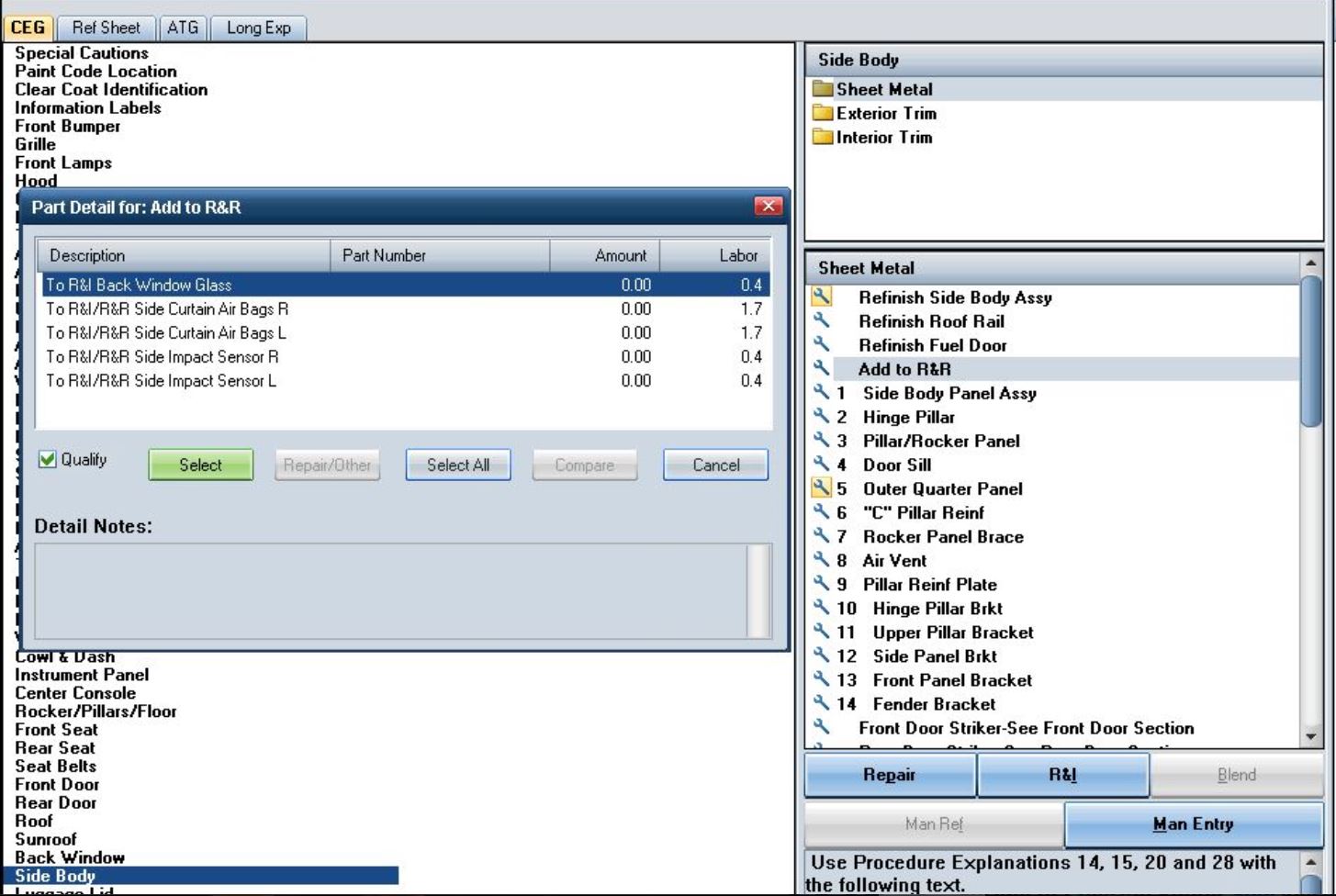

Estimating Tip: Mitchell – Add to R/R with 3rd row seat option

How to add optional R/R acessory items to Mitchell replacement operations.

Estimating Tip: Verifying OEM Repair Information

Recent DEG Inquiry on 2015 Lexus GX SUV revealed the importance of utilizing OEM repair information vs 3rd party “published” information without doing current dated information request.

The information currently available by the 3rd party service did not show an updated procedure to reflect the most current available procedure from the OEM. The scenario showed the engine must be R/I for access to replace the steering rack.

When verifying the procedure in the OEM subscription site, the most current OEM procedure from Lexus had been updated NOT requiring the engine to be R/I for replacement of the steering rack.

This could potentially cause labor not required or potentially missing required steps that is not reflected without the correct repair information

Estimating Tip: CCC New Feature: Disassemble and Reassemble Mirror Assembly

CCC Estimate tip: Impact to labor when replacing door shell and mirror

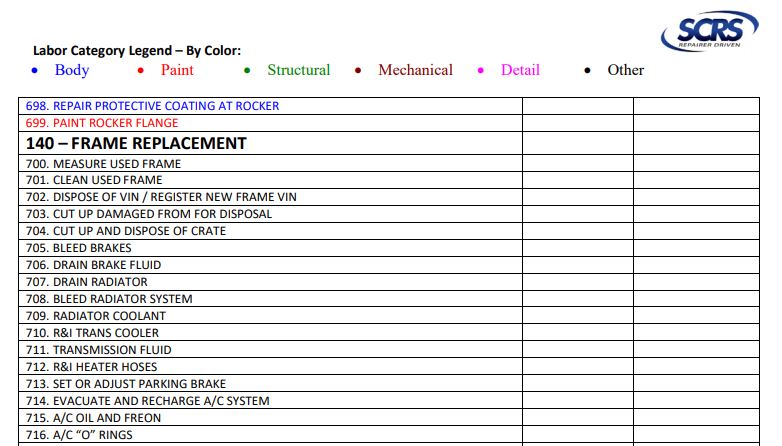

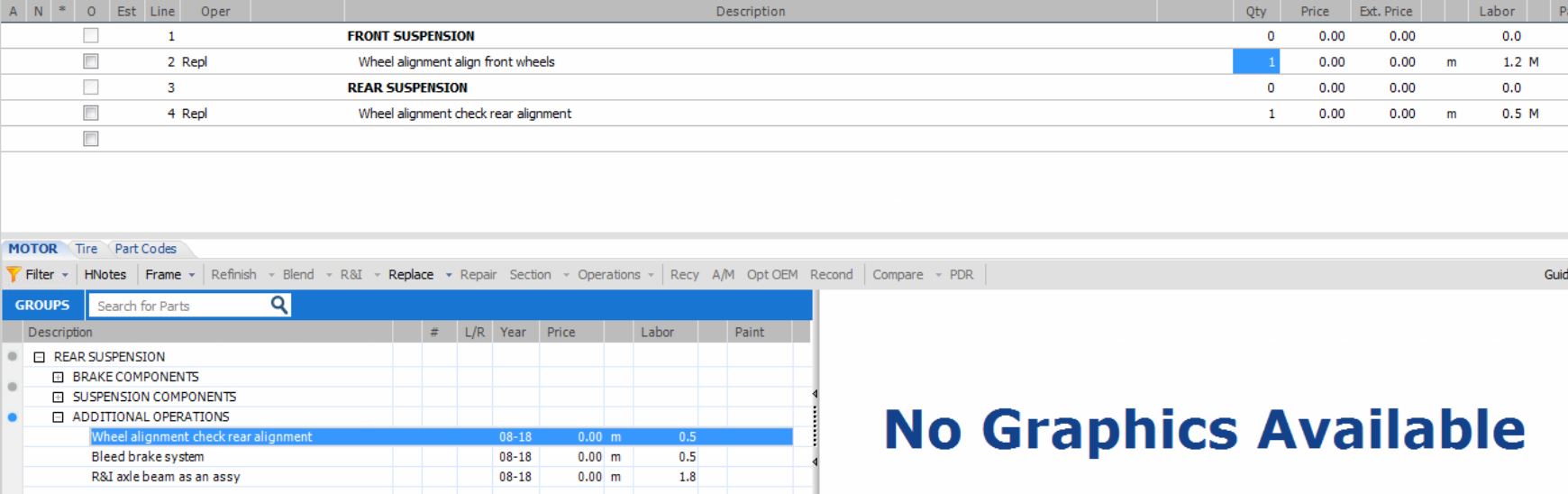

Estimating Tip: Mitchell – Frame Assembly R/R Additional Consideration

Mitchell CEG Collision Estimating Guide > Procedure Explanations > 9 Frame> Frame Assembly R & R

NOTE: Frame Assembly R&R requires planning. Proper preparation and job sequencing are key to performing this operation. Also, special equipment, additional workspace and manpower may be needed.

NOTE: It may be necessary to transfer parts from the damaged frame or order new parts to use on the new frame. This cannot be determined until you see the new frame. The needed additional time for this operation must be estimated.

We also suggest utilizing SCRS Guide to Complete repair planning page 17 for additional considerations to frame replacement.

Estimating Tip: CCC – Truck bed / Pick up box replacement requiring seam sealer application

DEG inquiry 14705 states

According to the MOTOR Guide To Estimating: duplicating the “OEM Caulk/Seam Sealer” for an OEM replacement “Hood, Door, Trunk Lid, Liftgate, Tail Gate and Pickup Box”, is not Included in the Motor estimated work time.

This is due to a variation in supplied OEM Service Parts that require “Caulk/Seam Sealer”. The “Caulk/Seam Sealer” may or may not be applied to the OEM Service Part, and if it is “Caulk/Seam Sealer” it may be Partial “Caulk/Seam Sealer” or Complete “Caulk/Seam Sealer”.

MOTOR suggests using an on-the-spot evaluation to determine if duplicating the “OEM Caulk/Seam Sealer” is required, and all parties mutually agree upon an appropriate “Caulk/Seam Sealer” time.

Estimating Tip: CCC, Audatex and Mitchell- Masking for stone guard

CCC/MOTORS have updated the GTE pages define that masking operations needed for “stone chip guard” coating is NOT INCLUDED.

Mitchell includes basic masking for “gravel guard” application using their formula “add .5 hour for the first major panel and .3 hour for each additional panel.”

Audatex: Page 148 Audatex DBRM Does not include masking in the application of gravel guard.

Estimating Tip: Audatex- How incorrect option and accessories can impact your Audatex Estimate labor time

Estimating Tip: CCC, Audatex and Mitchell – A/C Leak Test

Repairs involving air conditioning systems may need a leak test after the system has been recharged. The labor needed to perform a leak test using the various equipment available is NOT INCLUDED and would be an on the spot evaluation. Some testing kits may use a consumable product that must be injected into the system which is also NOT included in the labor time.

Estimating Tip: CCC- Retroactively apply labor rate to supplements and estimate of record.

Estimating Tip: Mitchell – How to add additional labor operations for Radiator Supports

Estimating Tip: Audatex – 2019 Update to Audatex DBRM Guide

Audatex Has just updated the DBRM Guide for 2019-2020.

The following updates have been made:

• Check marks added to the Rocker Center Pillar included operation. (Section 4-3 pg. 79)

• Strike out text: this will apply only to manufacturers known to supply raw, unprimed bumper covers. (Section 4-4 pg. 143)

• Add “Line Cap Off” (if required): a change was applied to any references of A/C Condenser: find “A/C Condenser R&I, including A/C line disconnect/connect (if required), Line Cap Off (when required).” (Multiple locations in DBRM)

• Continuous Clear: a continuous clear definition was added. (Refinish 4-4 pg. 134)

Estimating Tip: Audatex – Additional labor for headliner replacement

DEG Inquiry 14422 clarifies headliners being replaced may require modifications to fit additional components for vehicle specific options. Labor to perform “Repair, fitting or modification of new replacement parts (unless part is being sectioned)” is not included in our times provided.

This information is also available in Audatex DBRM Guide page 44 section 4-2 Labor Exclusions.

Estimating Tip: CCC, Audatex and Mitchell – Torqueing of fasteners

Torqueing of fasteners in the repair process is INCLUDED in published labor times.

Labor to look up or the cost associated with locating the torque specifications is NOT included.

Always consult OEM Repair procedures if any fasteners must be replaced as they may be onetime use.

Estimating Tip: CCC – Refinish overlap does not apply on panels refinished in a separate operation

Refinish Overlap does not apply to a component refinished during a procedure separate from the main component. This situation is covered in the “Guide To Estimating: Panel and Component Designation, Individual Procedure Items/Areas” as follows, “Areas of a panel or component that are part of a main component, but are refinished during a procedure separate from the main component. Example: edges, jambs, hinges, inside panels and the underside of hoods, deck lids, liftgates, etc.

No overlap deduction should be taken when calculating refinish time for items from this category.”

Please note:

The Estimating system is not able to determine if the Part is a different color or if it’s refinished during a procedure separate from the main component.

• This will require a manual deletion of the “Refinish Overlap” if the Part is a different color or if it’s refinished during a procedure separate from the main component.

• A combination of items from this category refinished during a single, continuous procedure should be subject to the appropriate “Adjacent” or “Non-Adjacent” overlap formula deduction.

The older Subaru Outback is example where the bumper cover is a separate color from the vehicle.

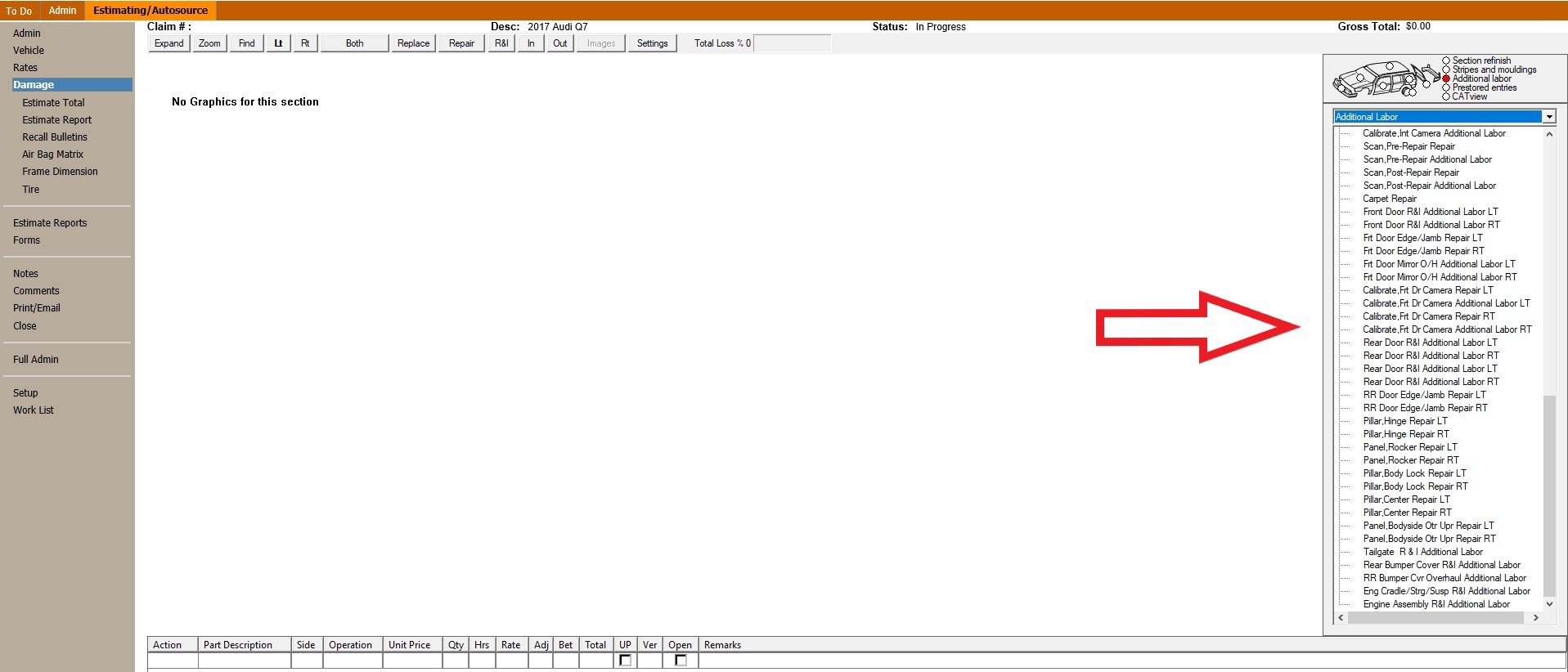

Estimating Tip: Audatex – Additional Labor > Calibration/ Scanning Operations

Audatex has been adding various scanning/ calibration operations to the database that may be applicable to the vehicle being repaired. Users can select from pre-defined calibration/ scanning operations in the “Additional Labor” section of the Audatex Database. The system does NOT provide labor or sublet cost.

Please note, this is NOT a substitute for using OEM repair information directly from the vehicle manufacture, but rather a good place to reference if a calibration may be needed on repairs you are performing.

Audatex July update:

Scan and Calibration Project*:

• 422 files have been updated with scan and/or calibration operations.

• 222 files now have a calibration operation available on the windshield glass

Estimating Tip: CCC, Audatex & Mitchell – Seem Sealer covering fasteners on bolt-on parts

Recent DEG Inquiries 14331, 14330 & 13329.

Some vehicles may have seam sealer/protective coatings over fasteners on bolt-on parts which may require additional labor to remove the seam sealer as well as re-applying seam sealers and protective coatings after reinstallation.

The process of removing seam sealer and re-applying as well as refinishing is NOT included in published labor times unless specifically noted in the database footnotes or labor report. Material cost is NEVER included in labor times.

An example of this would be on a Mercedes Benz Sprinter fender attachment location.

Estimating Tip: CCC, Audatex and Mitchell- Transferring of studs, brackets, braces

Recent inquiry 14245 New replacement parts may not come supplied with the appropriate mounting studs, brackets, braces.

Replacement labor for these parts are considered NOT INCLUDED unless specifically stated in the part footnote in the database.

CCC: Labor Time premise NOT INCLUDED operations:

-Brackets & braces transfer

Mitchell: CEG P-Pages > General Estimating Information > Labor General Information > Additions to Labor times:

Transfer Time

-For welded, riveted or bonded brackets, braces or reinforcements from old part to new part.

Audatex:Will need to refer to specific Audatex DBRM Guide and Section 4-3 of Audatex DBRM for specifics on Included and NOT included operations.

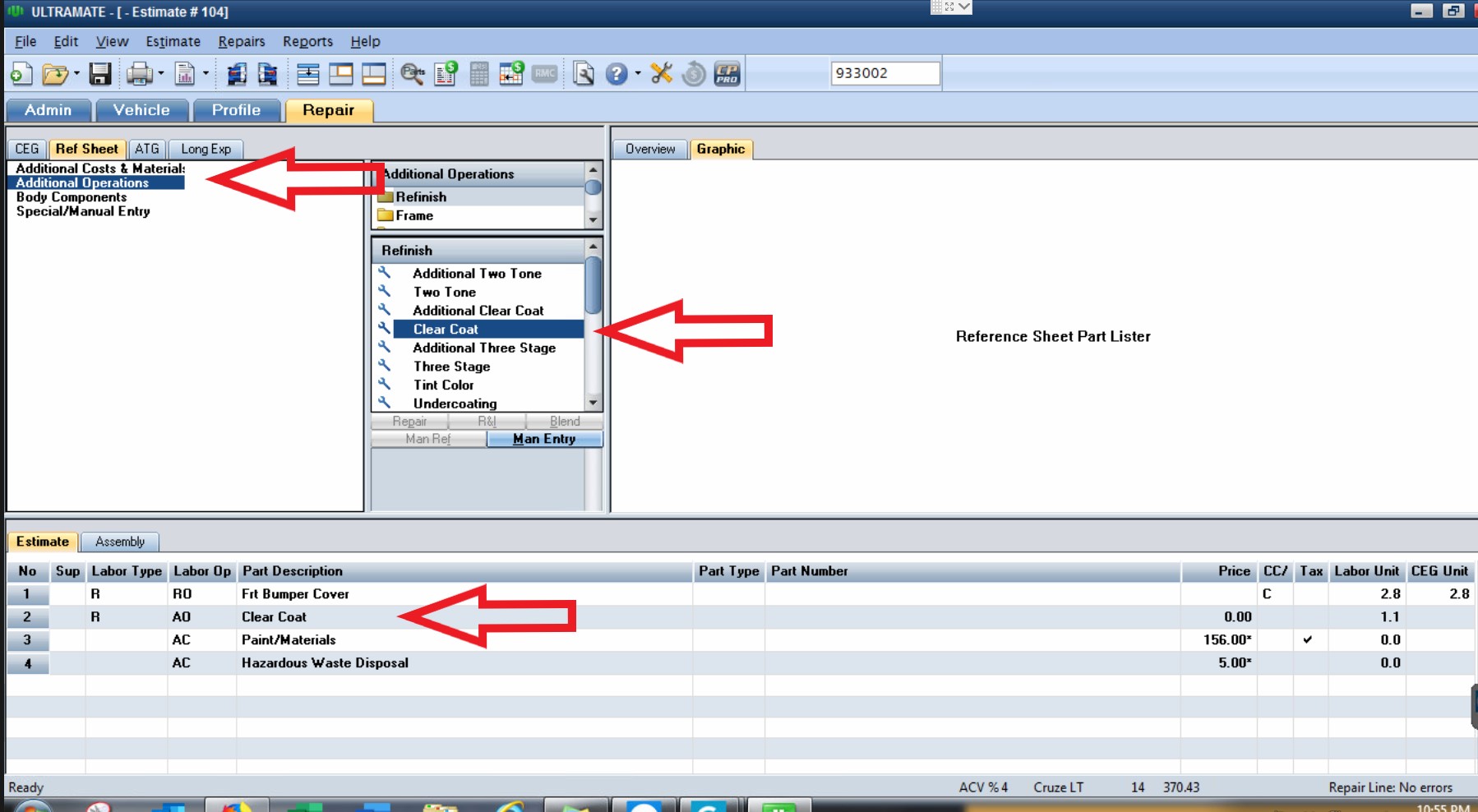

Estimating Tip: Mitchell – Automated Clear Coat Not Calculating on Estimate

Once you have deleted the clear line from an estimate, it will need to be added back manually. There is a prompt to identify it when you delete lines.

To manually select clear coat, users will need to click on the “REF SHEET” tab > “Additional Operations” >> Select clear coat and select the “Calculate Estimate” button and the system will re-add the clear coat calculation.

Estimating Tip: CCC – Trunk / Lift Gate Weatherstrip

Recent DEG inquiries 14234, 14151 and 14140 revealed database errors for trunk lid/ lift gate weatherstrip.

Weatherstrip attached to the body of the vehicle is NOT INCLUDED in the replacement time of the trunk lid or lift gate section of the database unless specifically stated in the detail line notes of the database.

It is important to verify this operation is not being INCLUDED unless there is a note or another component of the vehicle is being worked on where the weather strip would then be included (I.e. replacement of rear body panels unless specifically noted otherwise).

If users experience an issue where they feel the weatherstrip should not be included because of database error, please submit an www.degweb.org inquiry and we will work with the appropriate IP to resolve the issue.

Estimating Tip: CCC – Van / SUV – Side & Corner Panels

“Van and SUV” have a separate set of labor inclusions and not included operations on side panel / corner panel (quarter panel) replacements vs a standard vehicle application. It is important to refer to the correct section of the guide when performing a replacement and ensuring the correct not included operations are being listed correctly.

Example of common error is the NOT INCLUDED operation of the 2nd and/ or 3rd row seats if r/I is needed. The database may show INC when selected, but the p pages state otherwise.

Any errors found during the estimating process, please submit a DEG Inquiry to correct the situation with the appropriate information provider.

Estimating Tip: Audatex – Understanding Overlap in Audatex

“There are two methods of overlap deduction. They are:

• Guide Number Order: This method will include an operation on the lowest guide number first and then not count it on any higher guide number.

• Internal Labor Coding: In this method, labor operations are internally coded within the Audatex system. Related groups of operations that are collectively required to perform one specific operation are internally coded to allow the Audatex estimate to include commonly performed operations. When this type of coding is done and the main operation has been included in the estimate, the subordinate operations will generally be accounted for in that main operation. If the main operation is not selected, the subordinate operations will be accounted for by the guide number order method.

Inner panel labor is with outer welded panel removed. The labor on the estimate for these parts is after applicable overlap is deducted.”

Estimating Tip: CCC, Audatex and Mitchell – Test Fitting / Additional Alignment of Replacement Parts and Adjacent Parts

CCC/ MOTOR: GTE> Labor Time Premise “Trial-Fit of a component to verify dimensional accuracy of adjoining parts”

Mitchell: CEG Guide> Labor General information > “Repair or Align Parts or adjacent to parts being replaced.”

Audatex: DBRM> Page 47: “Does not include any duplicated effort such as test fitting.”

An example of these circumstances would be during replacement of a quarter panel, and having to perform additional adjustments to the adjacent door and/or trunk lid to ensure proper fit of the replacement quarter panel.

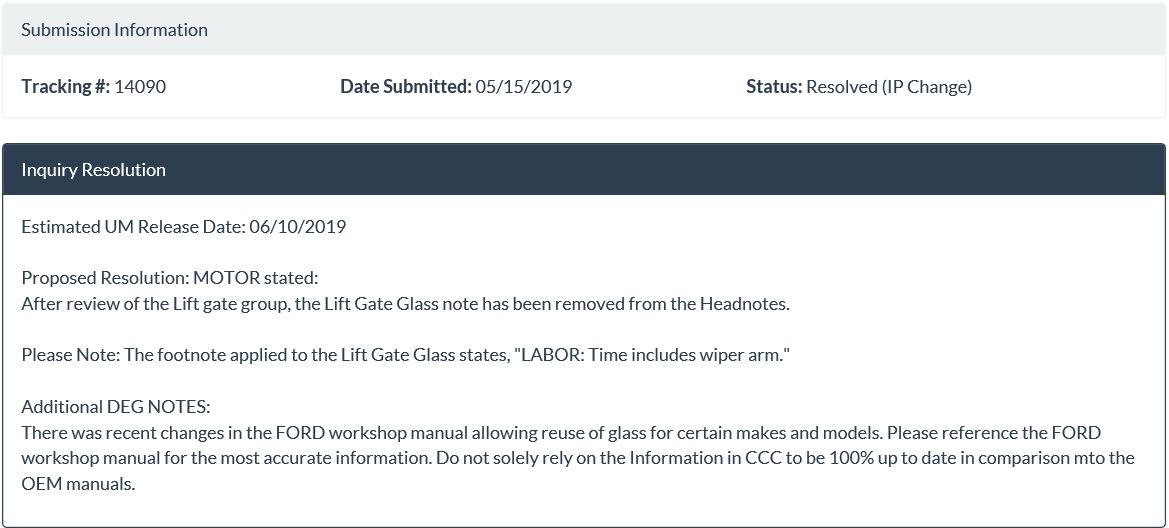

Estimating Tip: CCC, Audatex and Mitchell – Accuracy of Footnotes in Estimating Systems

Some vehicle chapters in all three information providers may list specific notes about a part being one time use or specific information from the OEM. It is important to confirm this information directly in the OEM service repair manual from the OEM direct. Solely relying on 3rd party information may not be the most up to date information available while the information providers are updating the systems to reflect.

Example of this scenario would be recent inquiry 14090 where the footnotes reflected information that was changed by the OEM in 2018.

Estimating Tip: Mitchell – Refinish on Repaired / Used Panels

Labor times related to repaired and/or used panels—example: Remove and install or masking of glass, outside handles or exterior trim, feather prime & block, masking for primer surfacer application—are not included in refinish time. The steps required for refinishing a repaired and/or used panel may vary from those required for a new panel depending on the condition of the repaired and/or used panel.

Estimating Tip: Audatex- Additional Set up NOT INCLUDED for Interior surfaces, edges and jambs.

Audatex DBRM section 4-4 Pages 134 and 135 TWO and THREE stage “Interior surfaces” states “Does not include additional time for setup”.

If refinishing interior, edges, and or undersides in a separate booth cycle, additional “SET UP” is NOT INCLUDED and would be an on the spot evaluation with manual line entry. Audatex defines “set up” to the following operations:

• Add Flex Additive

• Clear Clean Gun

• Gather materials, equipment, and tools

• Mix clear coat

______________________________________________________________________________

Two-stage Interior (Audatex DBRM Page 134)

• Provides 20% additional refinish time for two-stage of edges, jambs, undersides and interior panels (not including trim) when selected

• Does not include additional time for setup

• Does not contain a threshold time allotment

• Does not apply to the 2.5 hour threshold for two-stage exterior

• User-defined threshold will not apply when used in conjunction with two-stage exterior,

user-defined

• Produces a message at the bottom of the estimate explaining the two-stage calculation on the estimate

• Prints with other options on the estimate.

Three-stage Interior Surfaces (Audatex DBRM Page 135)

Provides 35% additional refinish time to three-stage edges, jambs, undersides and interior panels (not including trim) when selected.

• Does not include additional time for setup

• Does not contain a threshold time allotment

• User-defined threshold will not apply when used in conjunction with three-stage exterior surfaces

• Prints with other options on the estimate

Estimating Tip: CCC, Audatex and Mitchell – Road Testing for Diagnostic and Repairs

Road testing/test driving a vehicle for diagnostic purposes or to road test a vehicle after repairs are complete is NOT INCLUDED in all three estimating system IP’s.

Road Test is only included to verify alignment after completion.

Some vehicle OEM’s may require this process to reinitialize the vehicle after scanning and calibration is complete to ensure the vehicle systems are functioning properly.

Considerations for road testing may require cost of fuel as well as vehicle owner approval.

Estimating Tip: CCC, Audatex and Mitchell – Tinting Primer Sealer

Some paint manufactures may require a tinted primer sealer to help achieve better coverage/ transparency of the basecoat.

The labor to tint the sealer is NOT INCLUDED in the included refinish time of applying sealer to new undamaged panels prior to basecoat. Material cost associated with tinting sealer is NOT INCLUDED in labor allowances.

Estimating Tip: CCC, Audatex and Mitchell – Welding Supply Consumables

Labor for welded panel installation does not include the consumable materials needed when welding. Examples of consumables for welding may include the following:

• Welding Wire (Bohler Union x96, Brazing wire, Er70s-6, OEM Specific Alu wire etc.)

• Shielding gas

• Welding Tips

• Cost of OEM Specific welding coupons

• Coatings required by OEM for welding

• Spark Deflection material

• Labor for protecting the vehicle from welding and sparks

Estimating Tip: CCC, Audatex and Mitchell – Refinish Impact Bars

Refinishing of Impact Bars/ Bumper reinforcements is a NOT included operation in all three estimating systems.

Mitchell/Audatex may have a labor value available in the database to select from.

CCC/MOTORS does not provide labor values for this operation for the following reason.

Estimated Release Date: Closed

Proposed Resolution: MOTOR stated:

After review, MOTOR has determined that paint found on factory installed impact bars is an artifact of the factory refinish process (over-spray). Impact bars may come from the factory refinished in various stages of completeness and quality.

MOTOR does not take the position that the impact bar should not be returned to pre-accident condition. However, determining the estimated work time to refinish impact bars in various stages of completeness and quality, if refinished at all, is best left up to the judgment of estimators using an on-the-spot evaluation.

Estimating Tip: CCC, Audatex and Mitchell- Refinish Back sides and undersides

Refinishing back side of replacement/ repaired panel in all three estimating systems is NOT INCLUDED in exterior refinish times. This may require the user to make a manual line with an on the spot evaluation to replicate the factory appearance.

CCC:

UNDERSIDE COLORS

Refinish times presented in this guide are developed under the premise that the underside and jamb color is the same as the exterior body color. Some vehicle manufacturers use a different color for the engine compartment, trunk compartment and/or jambs. An additional paint mix is required if the underside and/or jamb color is a different color than the exterior body color. Clear coat (gloss or matte) will be required for base color coat applications. Some component backsides of vehicles may not be refinished; however, the OE replacement component may be supplied in a different E-coat color than the damaged vehicle. These factors should be considered when developing the estimate.

Mitchell:

It may be necessary to tint or otherwise modify non-exterior colors applied to undersides, edgesand/or jambs for which there is no paint color formula to achieve a color match. When necessary, reference “color match or tinting” listed above in Not Included Operations

Audatex:

Interior/Exterior Metal:

Refinishing interior surfaces of exterior parts (e.g., inner quarter, rear body panel, windshield pillars, etc.) requires more masking for interior protection than similar sized/construction exterior parts. Although preparation, application and color match were similar on both exterior and interior parts, interior parts required less time than exterior.

However, overall time required for interior versus exterior tended to be comparable, due to additional time required to protect the interior, combined with difficulty of access. Some of the same processes that apply to exterior parts were occasionally observed in refinish of interior parts, although not with the same care and attention given to exterior panels.

“Audatex does not include refinish labor for roof or bed underside. Under hood, interior parts (core support, frame, inner fender, etc.) tend to have less effort invested for color match or attention to detail in surface preparation than exterior parts do. In some instances, these panels are painted prior to installation (e.g., bolt-on radiator support panel). “

Estimating Tip: Mitchell – 2.5 Clear Cap Exclusion

Included Operations

• Mix material

• Clean and tack surface

• Apply material

• Clean equipment

NOTE: For NEW, UNDAMAGED PARTS, a total of no more than 2.5 hours should be necessary to perform the four Clear Coat Refinish Included Operations listed above. This calculation DOES NOT APPLY to bumper covers, ground effects, special package equipment, interior edges, jambs, entryways, undersides and additional time that may be required for repaired and/or used panels. It DOES NOT APPLY to complete vehicle refinish. It is not intended to determine the quantity or cost of materials required for the application of clear.

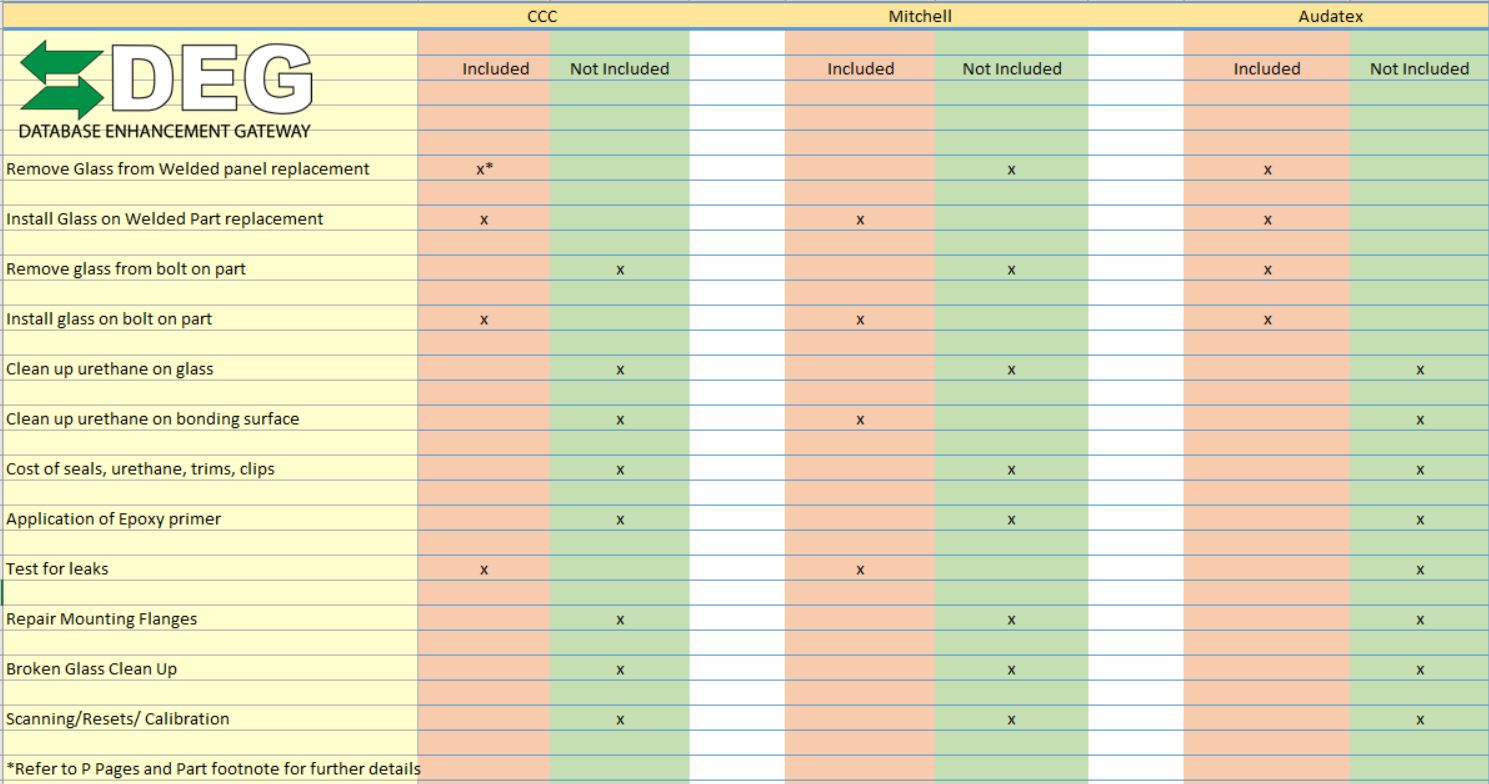

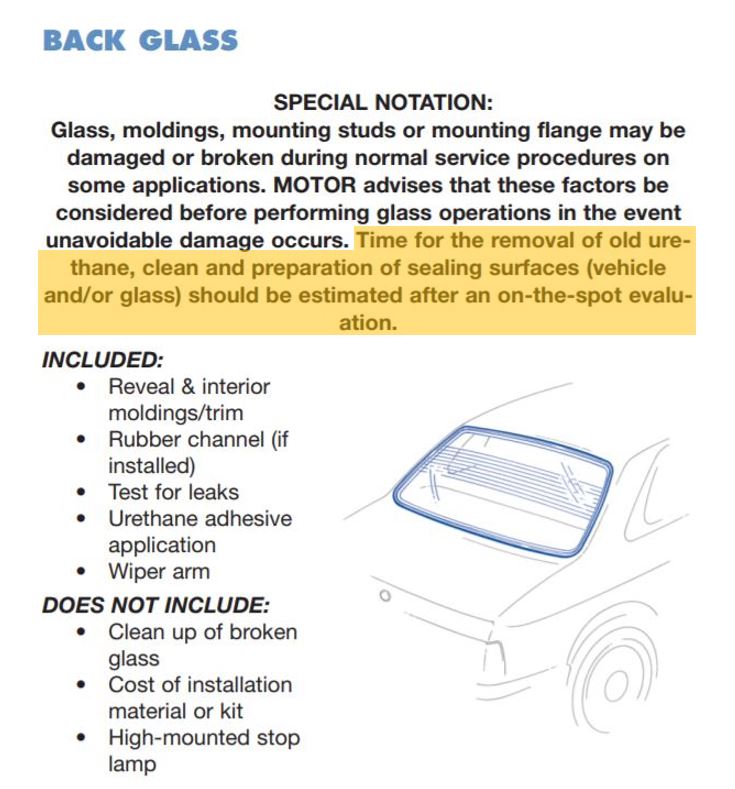

Estimating Tip: Quick Reference Chart – Bonded Glass Chart

Quick Reference guide of included and not included operations for Bonded glass in various repair situations.

Always refer to OEM repair instructions for correct supplies required to install as per OEM documentation.

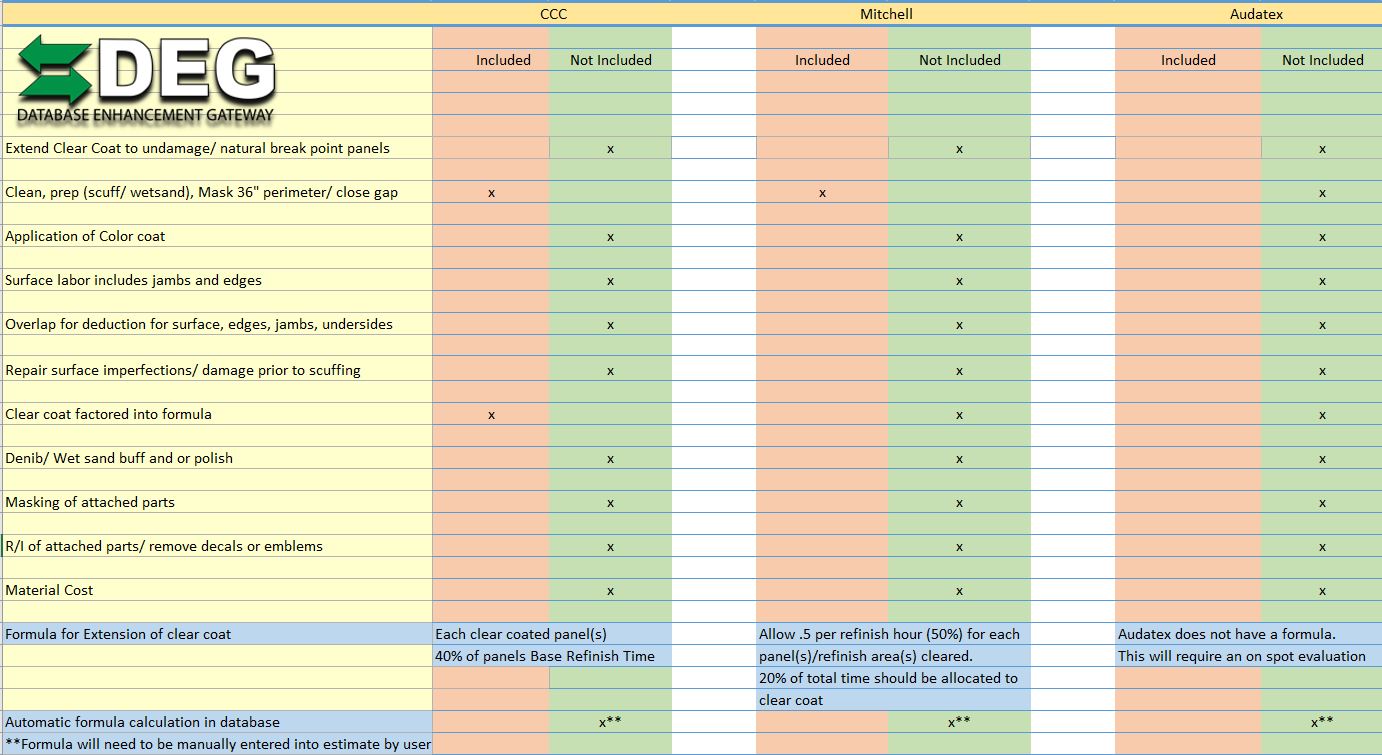

Estimating Tip: Quick Reference Chart – Extension of Clear Coat

Repairers may need to extend clear coat to the nearest natural breaking point / panel edge to maintain a refinish warranty on repair work. Please reference the chart of included / not included operations related to this topic.

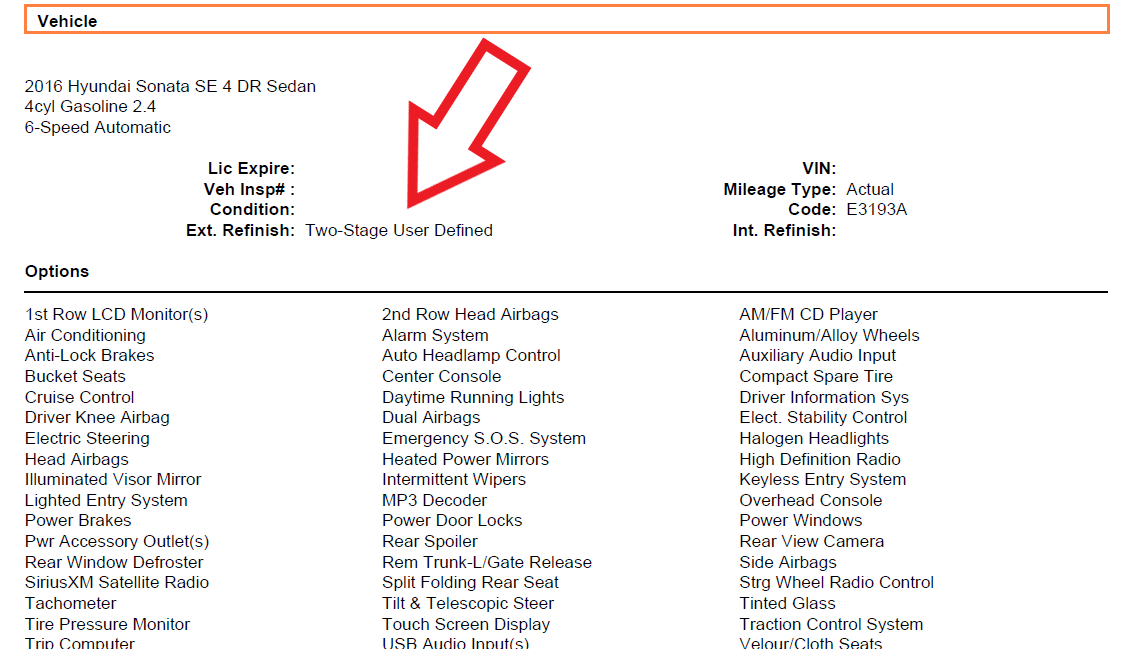

Estimating Tip: Audatex – Two-Stage Setting Override

It is important to note the paint settings on the estimate which can affect the labor calculations. To determine the correct paint profile, please reference the vehicle section of the estimate under “Ext. Refinish”.

Two Stage Setting Override

Audatex now offers an additional choice for default exterior single / two stage setting.

Prior to Audatex Estimating 8.06, AudaVIN color decoding would override the default single / two stage exterior setting from the Admin module. This behavior is still the default as AudaVIN properly decodes single / two / three stage color when option color information is received from the manufacturer.

As a new provisioning option, Audatex Estimating now offers a setting that ignores AudaVIN information for the exterior paint and retains the default exterior single / two stage default selection that is setup in the Admin module.

Estimating Tip: Audatex – High Build Primer Application

Section 4-5 of Audatex DBRM states that application of “High Build Primer” is not included in refinish labor. If a welded replacement panel requires the use of such product and material, labor to apply “High Build” Primer is NOT included and would be an on the spot evaluation for the labor and materials used.

Labor to block sand the “High Build” primer in “the seamed areas, to bring the panels to the condition of a new, undamaged panel for the purpose of refinish” would be included in the panel replacement time.

Second and/or third car bagging/cover car and masking operations are NOT included.

As always, material cost is never included in Audatex Labor Guides.

Estimating Tip: CCC- Oversized Vehicle / Equipment Set Up

Recent DEG Inquiry 13416 provided feedback: “Set up of scaffolding/ladders is ‘Not Included’ and would be an ‘On the Spot Evaluation’.”

Various type of vans, trucks or commercial vehicles may require repairs done above ground level, additionally requiring various types of tooling and equipment to be brought up to a safe working height.

When performing repairs on oversized vehicles, requiring the technican to work on a specialized aperatus: repairers should take into consideration the extra work required when utilizing scaffolding, ladders, lift-type equipment for both the technician and tool.

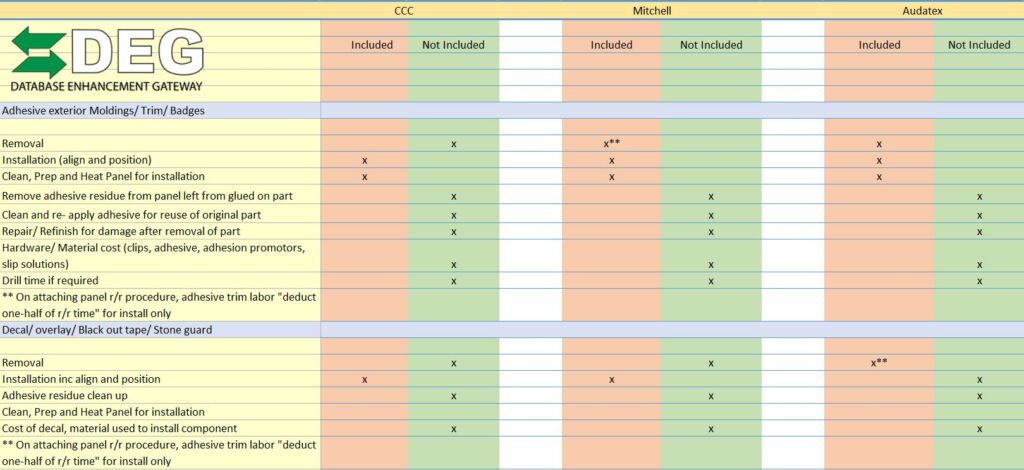

Estimating Tip: Quick reference chart Moldings and Decal operations

DEG has made a quick reference chart showing included and not included operations for moldings and decals for repair situations. Click here to download the latest quick reference chart

OEM service information may indicate a part is Non Reusable. Additionally All three Estimating IP’s recognize this with a note in their guide

CCC:

Damaged or Non-Reusable Moldings and Fasteners

Some moldings may be damaged or broken during normal R&I procedures. Additionally, some plastic or metal fasteners may be damaged and their ability to be reused jeopardized because of single-use design, age or exposure to the elements. Moldings, emblems and trim attached using a heat stake method are considered to be non-reusable. Caution should be taken while removing all fasteners, both metal and plastic. MOTOR recommends these factors be considered and mutually agreed upon before finalizing any repair cost estimate.

Mitchell:

Non-Reusable Parts

Some attachment components may not be suitable for reuse (examples: plastic clips, fasteners, suspension bolts). Caution should be taken when estimating removal and/or replacement. It should be agreed upon as to what parts may require replacement even though not noticeably damaged.

Audatex:

Page 129 Audatex DBRM

Moldings / Nameplates

Important Reminder:

Adhesive moldings may not be reusable.

Estimating Tip: Mitchell – Navigating multiple part schematics within a part group

Mitchell users may find that not every part is shown when selecting a vehicle part group, and will have to go down the list of part descriptions to see if additional parts exist. Users can quickly identify if multiple parts schematics exist for that group by locating a page number in the schematics screen menu. DEG has made a quick video showing how to navigate this process.

CCC: Estimate Sequence

It is important for estimators to use the database with “estimate sequence” in mind, which is the order that the repair plan is developed: front to back or back to front. Following the sequence provided by the database will also allow the database to properly calculate any overlap for adjacent panels for both refinish and panel replacement procedures.

The DEG has made a video tutorial of how to make profile setting adjustments or sequence setting inside the estimate itself, and what to look for when writing in the proper order of overlap deductions.

Audatex: Mirror overhaul feature

Starting this month (January 2019), Audatex will begin to support overhaul operations for some door mirrors. Mirror overhaul applies when a mirror assembly consist of many individual parts, i.e. side markers, cameras, puddle lamps, motors, sensors, etc. The overhaul operation includes the labor time to transfer individual mirror components from the damaged mirror to a new one. This new operation eliminates the need to search and add R&I for each mirror component, which in turn saves time and increases accuracy. The first four files with this enhancement include:

• 2018-2019 Honda Accord

• 2019-2019 Nissan Altima

• 2015-2019 Ford F150 Super Crew

• 2015-2019 Ford F150 Stdr Cab

• 2013-2019 Ford Escape

• All future files, new and updated, will have the mirror overhaul operation added when and if applicable.

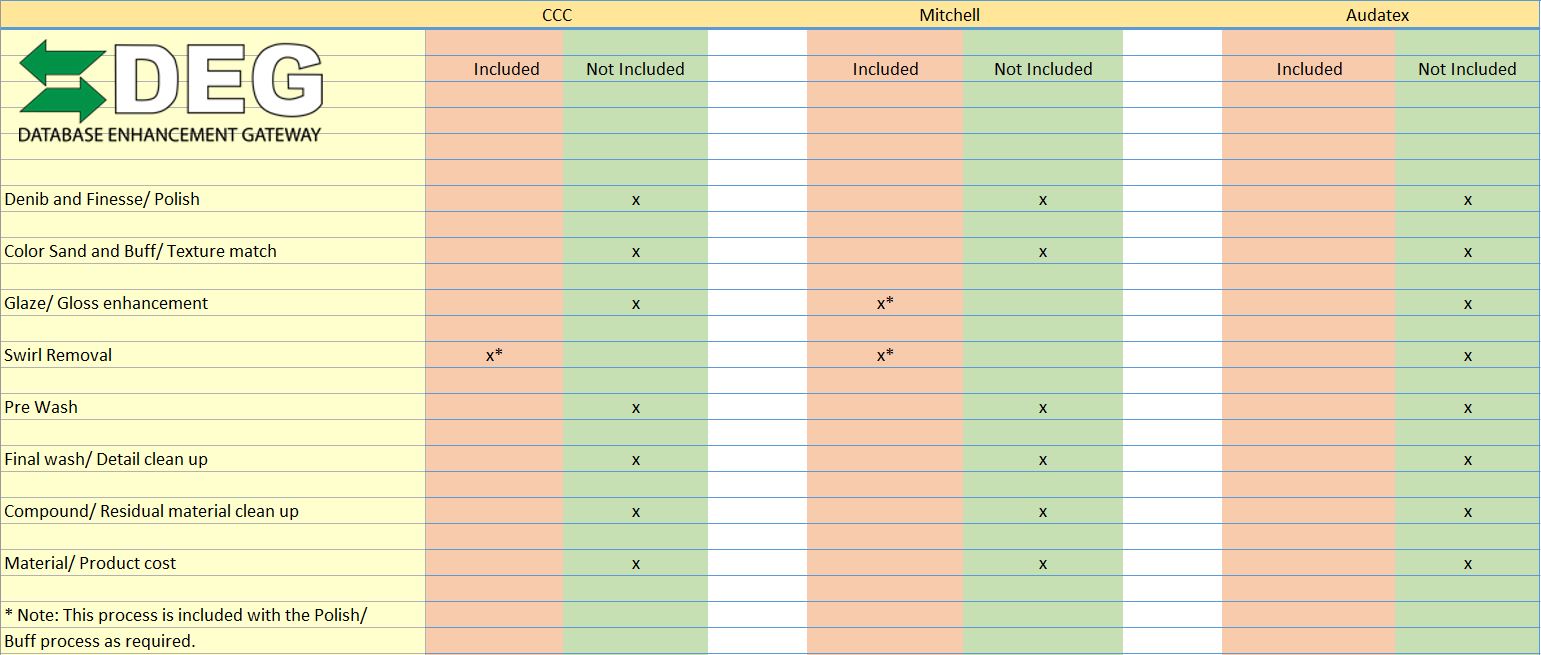

Estimating Tip: CCC, Mitchell & Audatex – Detail & Polishing

Users can quickly compare included and not included operations for detail and polishing operations across all three estimating system IP’s using the chart attached to the image below. Detail and Polishing quick reference chart

Estimating Tip: Audatex – Engine and Mounts Suspending

Audatex DBRM Guide Page 157 FAQ’s

Question: Why does the labor report only show minimal labor related to the engine and mounts (Combination Engine) when the engine must be suspended using a special tool?

Answer: There are a number of different tools and methods that could be used to support a drivetrain. Each may require different levels of preparation. The Audatex labor allowances do not take into account any special equipment or procedures necessary to prepare the drivetrain to support and only allows the labor to raise and support (Combination Engine) after the engine is prepared for the support tool and

any special tools are mounted.

Estimating Tip: Mitchel- Labor Times

THE LABOR TIMES SHOWN IN THE GUIDE ARE IN HOURS AND TENTHS OF AN HOUR (6 MINUTES) AND ARE FOR REPLACEMENT WITH NEW, UNDAMAGED PARTS FROM THE VEHICLE MANUFACTURER ON A NEW, UNDAMAGED VEHICLE.

Any additional time needed for collision DAMAGE ACCESS, ALIGNMENT PULLS, NON-ORIGINAL EQUIPMENT or USED PARTS should be agreed upon by all parties. Times for some operations are applicable after necessary bolted, attached or related parts have been removed.

Exceptional circumstances, including all the sub-operations or extra operations, are indicated as notes throughout the text or are identified in the Procedure Explanations.

The actual time taken by individual repair facilities to replace collision damaged parts can be expected to vary due to severity of collision, vehicle condition, equipment used, etc.

Estimating Tip: CCC, Audatex & Mitchell – (M) Mechanical Operations for Scanning Operations

All three Information providers, CCC, Mitchell and Audatex, acknowledge that scanning operations required during the repair process is a (M)/ Mechanical process.

CCC has confirmed that it plans to add the (M) feature to the database shortly.

Both Mitchell and Audatex already designate the operation to Mechanical when selected from the database.

Users may still need to manually input the (M) coding depending on the IP they are using.

Estimating Tip: CCC, Audatex & Mitchell – Charging Battery / Maintain Battery Voltage

Certain repair situations may require the on board vehicle battery to be connected to a battery charger/ battery maintainer during repairs.

Example of this situation is during the scanning process.The OEM may state the vehicle must maintain a certain voltage to ensure all modules, computers, and electrical consumer equipment are being scanned at the proper voltage level. Battery charging/ Battery maintenance is NOT INCLUDED in developed labor times and would be an on the spot evaluation.

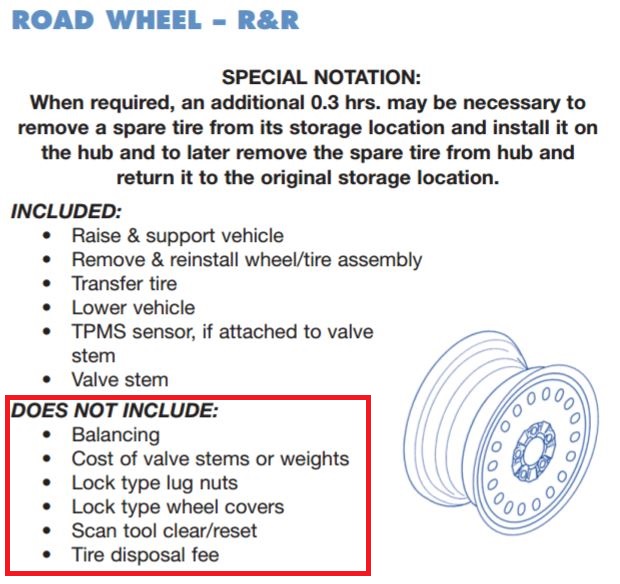

Estimating Tip: Information on Tire Replacement

Repairers may find it challenging to find information regarding tire replacement documentation and when to replace all four(4) or two(2) tire’s to match the opposite side on the same axle.

Some OEM Repair websites may not have this information listed. DEG Suggests locating this information in the vehicle owners manual which would typically be found in the glove box of the vehicle or found online using the digital copy. Using the index of the manual, look up “tires” or “tyres” for quick search of the manual.

DEG has made a spread sheet of all major vehicle manufacturer links to access owner’s manuals online in digital format.

Manufacture owners support weblinks.pdf

Estimating Tip: Mitchell – Air Bag / SRS Component Inspection and Replacement Tables

Mitchell has published a comprehensive list of parts and inspections required after SRS/ Airbag deployment. This information is available online here: http://static.mymitchell.com/static/webhelp/ppages/abt/1033/index.htm

Users will need to click on the “Air Bag/ SRS Component Inspection & Replacement” tab and select the appropriate manufacturer, model and year for the vehicle.

You are not required to be a Mitchell user/subscriber to view this information. This can be used as a quick reference chart/tool during the repair planning stages to determine vehicle repairability.

Disclaimer: This is not a substitute over OEM repair information. OEM Repair information is available by visiting www.oem1stop.com. Manufactures technical websites will always have the most current and up today information. You may be required to create a log in and pay for subscription cost to view and access OEM direct information.

Estimating Tip: CCC, Audatex and Mitchell – Additional Labor for ADAS Measurement

Vehicles equipped with ADAS Blind Spot Monitor systems may have a procedure in the workshop manual to measure the mounting bracket position. This procedure can be labor intensive and require additional r/I work to access certain control points on the vehicle. Labor to measure, verify and repair if needed is NOT INCLUDED and should be an on the spot evaluation.

Below example is from Honda Service Express showing 2016 Acura RDX. It is always important to look up the full procedure from the OEM to verify all measurements and instructions required.

Estimating Tip: All Three Estimating Systems – 2019 Chevy Silverado Database Update

All three information providers have provided feedback for the new redesigned 2019 Chevy Silverado database being released.

CCC

• 2019 Chevrolet 1500 Pickup: Estimated delivery from MOTOR to CCC is 11/30/2018. If received on this date, the data will be released to electronic users on 12/14/2018 or the January 2019 DVD release.

• 2019 GMC 1500 Pickup: MOTOR has not yet started development of this data at this time.

Mitchell

• 2019 Chevrolet 1500 Pickup: 2019 Chevy Silverado 1500 is currently scheduled to be available with the November 2018 (18.11) update/product release.

Audatex

• 2019 Chevrolet 1500 Pickup: Crew Cab – 1/19 release; Ext Cab – 3/19 release; Single Cab – TBD

• 2019 GMC Sierra: Crew Cab – 3/19 release; Ext Cab – 3/19 release; Single Cab – TBD.

Please note, the above information is based on current information available from all three IP’s. Changes to release date may be possible depending on development schedule.

Estimator Tip: CCC/ MOTORS – Updated P Pages GTE Guide

11/1/18 CCC/MOTORS has officially updated the P pages/ GTE Guide online and within CCCone estimating program. Click Here to view a live version of the CCC P Pages

A downloadable PDF Cope is also available by clicking here

The DEG has made a “Delta” Report of the changes/ and additions made. Click here to view a copy of the Changes made. To read more about the update

More information about the changes can be read on the latest RDN Article